In the fast-evolving world of packaging and printing, the demand for advanced Paper Coating Machines is on the rise. Recent industry reports indicate that the global market for paper coating technology is projected to reach $5 billion by 2026. Characteristics such as efficiency, precision, and cost-effectiveness play a crucial role in these machines. Manufacturers must stay updated with the latest innovations to meet this growing demand.

One of the standout features of modern Paper Coating Machines is their ability to apply coatings uniformly across varying substrates. This ensures high-quality finishes critical to consumer products. Advanced technology, such as automated settings and real-time monitoring, can enhance production efficiency. However, the reliance on technology is not without its pitfalls. Many machines may face calibration issues, leading to inconsistencies in the final product.

Furthermore, sustainability is a pressing concern. Energy-efficient models are gaining attention, yet identifying the right balance between efficiency and environmental impact remains a challenge. Constant improvement is essential, and manufacturers must be prepared for ongoing adjustments in technology and methods to stay competitive. The next few years will reflect the industry's adaptation to these challenges and innovations.

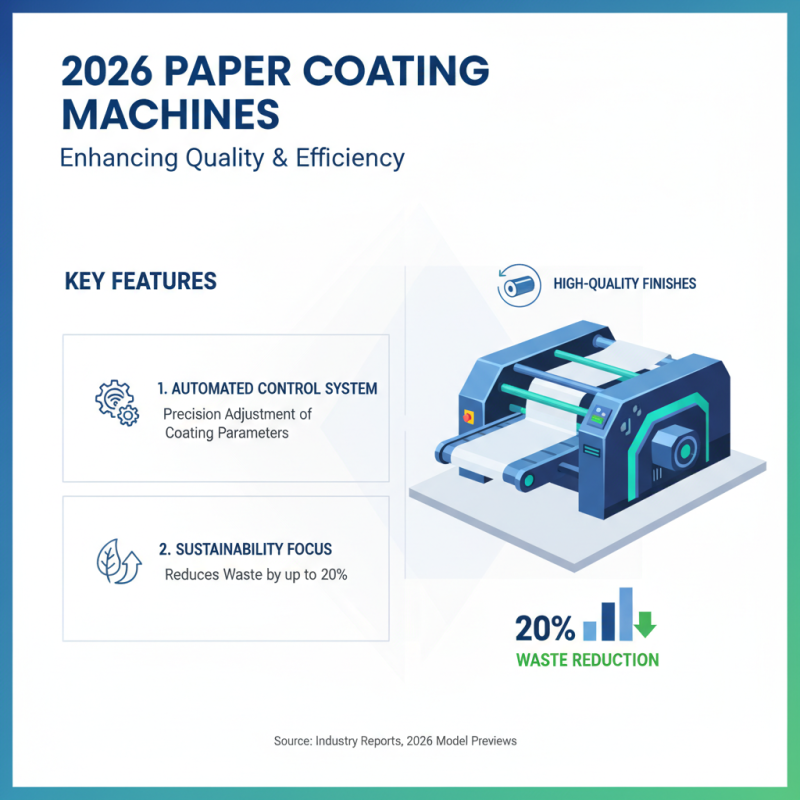

Paper coating machines are essential in achieving high-quality finishes in the paper industry. The 2026 models showcase innovative features designed to enhance efficiency. One notable feature is the automated control system. This system allows operators to adjust coating parameters with precision. Reports indicate that machinery with automated controls can reduce waste by up to 20%. This efficiency is crucial for sustainability.

Another impressive aspect of these machines is their speed. Modern paper coating machines can operate at speeds exceeding 300 meters per minute. This rapid output can meet the growing demands of the printing and packaging sectors. However, a challenge remains. As speed increases, maintaining consistent quality can be difficult. Companies must regularly calibrate their equipment.

Energy consumption is also a critical concern. New machines are designed to use approximately 15% less energy than their predecessors. This reduction not only lowers operating costs but also minimizes environmental impact. However, it's vital to note that transitioning to these advanced models requires significant upfront investment. Some companies may struggle to justify this cost amidst budget constraints. Balancing innovation and practicality is an ongoing challenge in the industry.

Advanced coating technologies have transformed paper production significantly. These innovations enhance the surface quality of paper, making it smoother and more efficient. One notable feature is the ability to apply coatings with precision, resulting in uniform coverage that enhances printability. The technology also allows for various coatings, including glossy and matte finishes. Each finish caters to different customer needs.

Another key benefit is the reduction of waste. Advanced machines use materials more efficiently, minimizing excess. They also optimize the drying process, which saves energy. However, not all paper production facilities have adapted. Some still rely on older methods, which can lead to inconsistencies. Improving training for operators could help bridge this gap.

Environmental considerations are essential. Sustainable coatings are becoming available, benefiting both producers and consumers. Yet, finding the right balance between performance and environmental impact remains a challenge. As producers experiment with new materials, the results can be unpredictable. These advancements open doors but also pose questions about reliability and cost-effectiveness.

In 2026, various paper coating methods continue to evolve, catering to diverse industry needs. One prevalent technique is the use of water-based coatings, which are environmentally friendly and easy to apply. Reports suggest that over 40% of manufacturers adopted this method due to its low VOC emissions. The performance remains strong, especially for packaging applications.

Another method gaining traction is UV-curable coatings. This approach offers faster drying times and a durable finish. Industry data indicates that UV coatings might see a 25% increase in use through 2026. However, some users report challenges with cost and specialized equipment requirements. Balancing quality and investment is essential.

Tips: When selecting a coating method, consider production volume and environmental impact. Evaluate initial costs versus long-term benefits. Test samples before full implementation to ensure desired results. User feedback is valuable for refining the process. Never underestimate the importance of an efficient drying system—it’s pivotal for maintaining quality.

| Coating Method | Features | Benefits | Application |

|---|---|---|---|

| Roller Coating | Continuous coating, adjustable thickness | High efficiency, uniform application | High volume production, packaging |

| Spray Coating | Versatile application, complex shapes | Excellent coverage, reduced material waste | Artistic and custom projects |

| Blade Coating | Uniform layer thickness control | High precision, minimal excess coating | Specialized applications, high-end finishes |

| Dip Coating | Simple process, immersion of materials | Cost-effective, good for large parts | Manufacturing components, mass production |

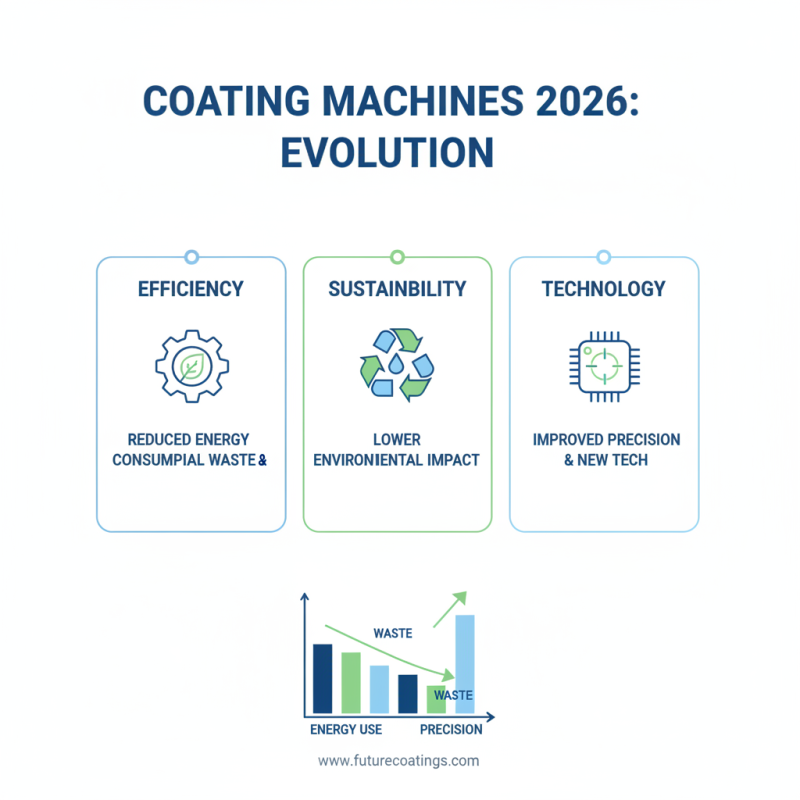

The evolution of coating machines in 2026 emphasizes efficiency and sustainability. Manufacturers focus on reducing energy consumption and material waste. New technologies improve precision and reduce environmental impact.

Many machines now integrate smart sensors. These sensors monitor and adjust parameters in real-time. This capability leads to better consistency and higher-quality coating results. It’s impressive how automation enhances production speed and accuracy.

**Tip:** Regular maintenance is key. A well-maintained machine runs more efficiently. Neglect can lead to higher energy bills and quality issues.

Additionally, sustainability features are becoming mainstream. Eco-friendly materials are being used in construction. This transition helps reduce the carbon footprint. Improved recycling methods also play a role. It’s not just about what you coat but how you do it.

**Tip:** Training staff on new technologies can enhance operational efficiency. Lack of knowledge can create bottlenecks in production. Investing in education leads to better outcomes.

The paper coating machine industry is evolving rapidly. In 2026, several market trends are shaping machine designs. Sustainability is paramount. Manufacturers are focusing on eco-friendly materials and processes. Energy-efficient machines are in high demand.

Digital integration is another significant trend. Smart technologies are enhancing operational efficiency. Manufacturers are adopting IoT solutions to monitor performance in real-time. This allows for predictive maintenance and reduces downtime. Automation is increasingly prevalent in designs too.

Tip: When selecting a coating machine, consider its compatibility with smart technology. Understanding this can future-proof your investment.

Customization is also becoming a standard requirement. Businesses want machines that can easily adapt to different paper types and coatings. This flexibility can boost productivity significantly.

Tip: Evaluate the adaptability of your potential machine. A versatile machine can save costs and time over its lifespan.

However, some manufacturers struggle to keep up with these demands. Constant innovation requires significant investment. Companies must balance adaptation with financial feasibility. This can lead to hesitations and missed opportunities.