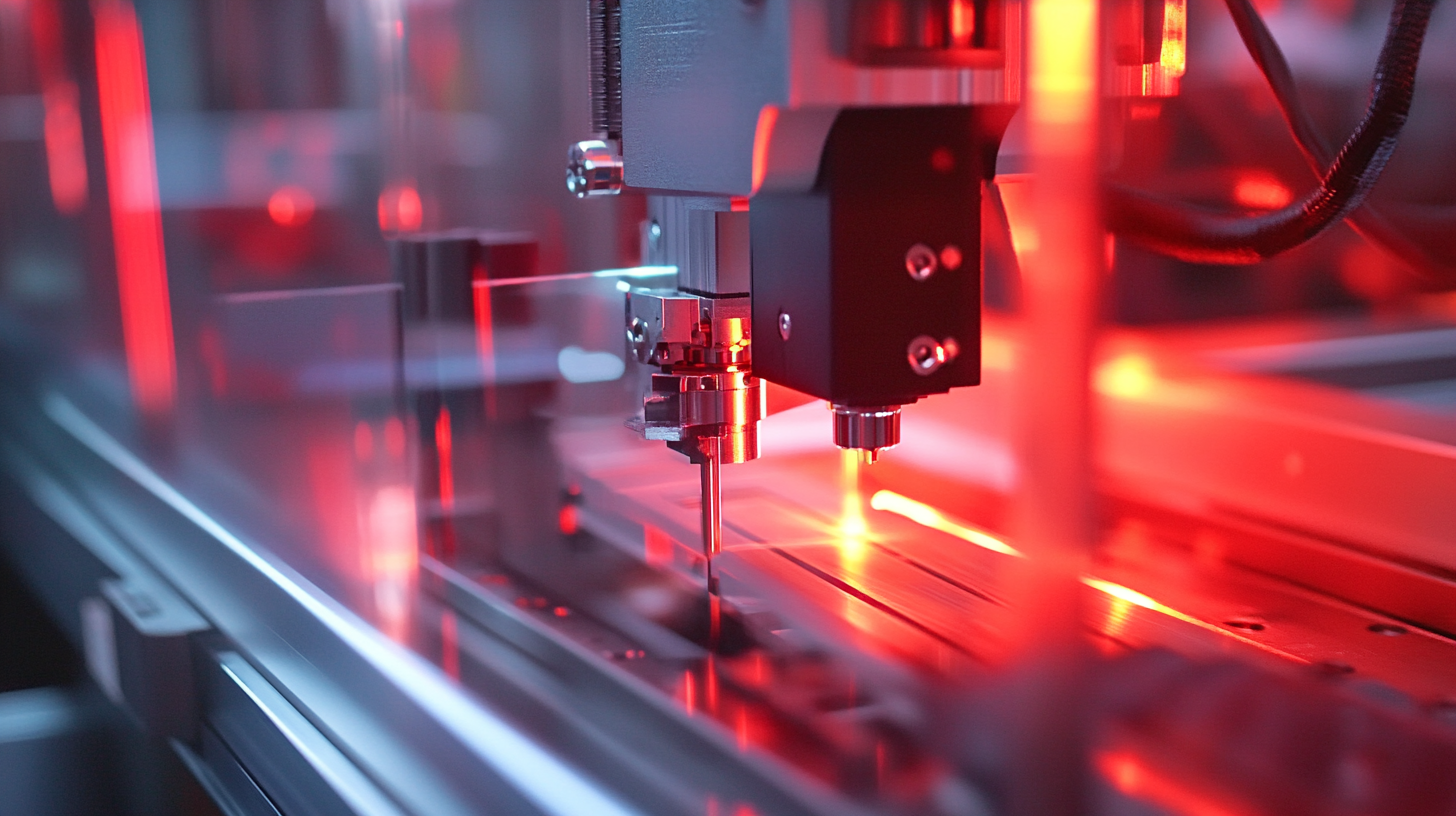

In the rapidly evolving landscape of manufacturing technology, precision and efficiency have become paramount for companies targeting global markets. The demand for high-quality coating solutions has led to significant advancements in the machinery sector, particularly with the rise of Comma Doctor Blade Coating Machines. According to a report by Smithers Pira, the global printing and coating machinery market is projected to grow by 3.7% annually, highlighting the critical role of innovative equipment in maintaining competitive advantage. These machines not only enhance the quality of coating applications but also improve operational workflows, making them essential for industries ranging from textiles to automotive. As we delve into the five key technical specifications that define the best Comma Doctor Blade Coating Machines, we aim to equip manufacturers and sourcing professionals with the insights necessary to make informed decisions in this dynamic market.

When sourcing advanced Comma Doctor Blade Coating Machines, understanding their key characteristics is crucial for maximizing efficiency and product quality. These machines are designed to ensure precise and uniform coating, which is particularly important in applications involving sophisticated materials like nickel cobalt manganese oxide (NCM) in battery production. Recent studies highlight how the amplitude sweep of cathode slurries, with varying solid content, significantly impacts the complex shear strain. This relationship underscores the need for machines that can finely tune their operational parameters to accommodate diverse material properties effectively.

Consider the importance of advanced mixing systems in these machines. A high-performance mixer can enhance the dispersion of materials, leading to improved slurry consistency and performance. Research indicates that a solid content that is too high can lead to inefficient dispersions, ultimately impacting the coating quality. Therefore, selecting a machine that offers flexibility in its settings is paramount.

Additionally, advanced monitoring systems that track viscosity changes in real-time can prevent production discrepancies. By maintaining optimal viscosity levels, manufacturers can ensure the final product adheres to stringent quality specifications. When choosing the right Comma Doctor Blade Coating Machine, always assess these technical specifications to guarantee superior outcomes in your production line.

In the realm of coating applications, precision is not just a luxury; it is a necessity. This is especially true for industries relying on comma doctor blade coating machines, where the uniformity and quality of the coating can determine the final product’s performance and aesthetic appeal. Understanding the significance of precision in these applications helps manufacturers achieve optimal results and maintain competitive advantages in the global market.

High-precision coating machines are designed to minimize variations in thickness and application consistency. This not only ensures that the coating adheres optimally to surfaces but also enhances the durability and functionality of the final product. With technological advancements, sourcing machines that incorporate state-of-the-art sensors and automation systems has become essential. These features allow for real-time monitoring and adjustments, ensuring that the coating process operates within specified tolerances. As a result, businesses can meet the stringent demands of various industries while upholding quality standards.

The chart below illustrates the average specifications of various coating machines used in comma doctor blade applications, focusing on precision-related features crucial for optimal performance.

When sourcing the best comma doctor blade coating machines, understanding key technical specifications is crucial for ensuring precision and efficiency. One of the top specifications to consider is the coating thickness adjustment capability. Machines that allow for micro-adjustments in coating thickness can significantly enhance the quality of the final product, catering to specific printing requirements.

Another important specification is the type of coating technology employed. Look for machines that utilize advanced technologies such as ultrasonic or high-speed jet coatings, which not only improve application accuracy but also reduce waste by optimizing material usage.

Lastly, consider the machine's compatibility with various substrates. Machines that can handle a wide range of materials will provide greater versatility in production processes. This adaptability is essential for businesses focused on global sourcing, enabling them to meet diverse customer needs effectively.

**Tips:** When evaluating machines, always request sample coatings and test runs to better understand their performance. Additionally, reviewing user feedback and maintenance requirements can provide insights into the machine’s reliability and long-term operational costs.

| Specification | Description | Importance |

|---|---|---|

| Coating Thickness Control | Precision control of coating thickness to ensure uniformity. | Critical for product quality and consistency. |

| Speed of Operation | Ability to adjust the speed of coating application. | Enhances productivity and efficiency. |

| Ease of Maintenance | Simple cleaning and maintenance procedures. | Reduces downtime and operational costs. |

| Integration with Automation Systems | Compatibility with existing production automation setup. | Improves overall manufacturing efficiency. |

| User-Friendly Interface | Intuitive controls for ease of operation. | Facilitates training and reduces operational errors. |

As we look toward 2025, the landscape of coating technology is rapidly evolving, promising exciting advancements that will revolutionize the industry. One of the most significant trends is the integration of smart manufacturing techniques. By utilizing IoT-connected devices, companies can achieve real-time monitoring and data analysis of the coating process. This transformation not only enhances precision but also optimizes the efficiency of comma doctor blade coating machines, making them indispensable for global sourcing.

Another noteworthy development is the increasing reliance on eco-friendly materials and processes. As sustainability becomes a priority, manufacturers are innovating to incorporate biodegradable and non-toxic coatings. This shift not only complies with regulatory demands but also meets the growing consumer preference for environmentally responsible products. The focus on sustainable practices will likely drive the evolution of coating technologies, ensuring that production remains both efficient and aligned with global ecological goals. By embracing these future trends, businesses can position themselves at the forefront of the industry, ready to meet changing market demands with cutting-edge solutions.

In the quest for optimal comma doctor blade solutions, global sourcing strategies play a pivotal role in ensuring manufacturers acquire the best technology available. As the industry evolves, companies must seek advanced machinery that not only streamlines production processes but also guarantees precision and consistency in product quality. Recognizing the technical specifications of high-performing comma doctor blade coating machines becomes essential in this competitive landscape.

Investing in reliable machinery entails understanding key features such as coating uniformity, automation levels, and ease of maintenance. These specifications not only enhance operational efficiency but also reduce downtime, ultimately leading to cost-effectiveness. Global sourcing allows businesses to tap into diverse suppliers who specialize in cutting-edge technologies, ensuring access to the latest innovations that can elevate production standards. By carefully evaluating these technical aspects, manufacturers can foster long-lasting partnerships that lead to superior product outcomes and greater market distinctiveness.