In the modern manufacturing landscape, efficiency and precision are paramount, particularly in the production of packaging materials. Among various innovations, the Aluminum Foil Coating Machine stands out as a pivotal technology that enhances the functionality and quality of aluminum foil products. This machine is designed to apply protective and decorative coatings, thereby improving the foil's resistance to moisture, heat, and chemicals. As industries ranging from food packaging to pharmaceuticals increasingly rely on aluminum foil, understanding the workings of these machines becomes essential.

The Aluminum Foil Coating Machine operates through a sophisticated process that involves the application of different types of coatings onto aluminum foil substrates. By utilizing advanced techniques, such as roller coating and spray coating, the machine ensures an even distribution of the coating material, ultimately leading to enhanced product performance and longevity. The coated aluminum foil not only meets the demands of various applications but also contributes to sustainability by reducing waste and improving recyclability. As we delve deeper into the mechanisms and advantages of the Aluminum Foil Coating Machine, we will uncover its vital role in transforming the packaging industry.

Aluminum foil is a versatile material widely used across various industries due to its unique properties. It is lightweight, malleable, and resistant to corrosion and moisture, making it an ideal choice for packaging, insulation, and even electrical applications. In the food industry, aluminum foil is commonly used for wrapping and cooking, as it helps retain heat and moisture, ensuring food stays fresh longer. In construction, aluminum foil serves as a reflective barrier that enhances energy efficiency by minimizing heat loss in buildings.

Moreover, aluminum foil plays a crucial role in the pharmaceutical sector, where it is utilized for packaging medications, protecting them from light and air, thus preserving their potency. Additionally, the automotive industry employs aluminum foil in various components to reduce weight and improve fuel efficiency. Its applications extend to decorative uses in arts and crafts, highlighting its adaptability in meeting diverse industry needs.

**Tips:** When working with aluminum foil, always consider its thickness based on the intended application; thicker foil offers better durability for cooking, while thinner foil is excellent for wrapping delicate items. Furthermore, when using aluminum foil for insulation, ensure that the shiny side faces outward to maximize thermal efficiency.

Aluminum foil coating machines are essential for various industries, providing a means to enhance the properties of aluminum foil through a specialized coating process. These machines serve the primary purpose of applying coatings that improve the durability, aesthetic appeal, and functionality of aluminum materials. The coatings can include protective layers, decorative elements, or even functional treatments to enhance properties like corrosion and heat resistance.

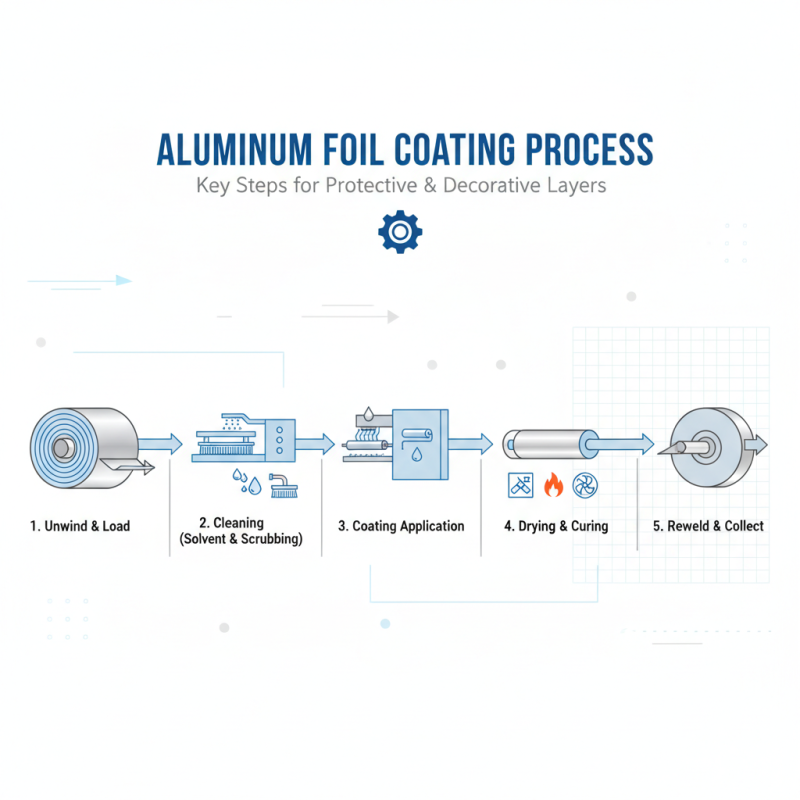

A typical aluminum foil coating machine operates by systematically unwinding the aluminum roll, passing it through a series of applicators that distribute the coating material evenly across the surface. After application, the foil is subjected to drying or curing processes to ensure the coating adheres properly and achieves optimal performance. The configuration of the machine may vary based on the specific requirements of the coating process, including the type of foil and coating used.

Tips for maximizing the efficiency of aluminum foil coating machines include regular maintenance checks to ensure all components are functioning correctly and keeping the coating environment clean to avoid contamination. Additionally, adjusting the coating temperature and speed according to the material specifications can greatly enhance the quality of the final product. Proper training for operators can also lead to improved performance and reduced waste during production.

| Feature | Description | Purpose | Common Applications |

|---|---|---|---|

| Coating Type | Polymer and water-based coatings | To enhance protective properties | Food packaging, insulation materials |

| Machine Type | Roll-to-roll and sheet-fed machines | To apply coating evenly | Manufacturing of foils and containers |

| Speed | Up to 300 m/min | To increase throughput | High-volume production environments |

| Control System | PLC and touch screen interface | For precision and ease of use | Monitoring and adjustments in real time |

| Customization | Various coating thickness options | To meet specific customer requirements | Tailored products for different industries |

An aluminum foil coating machine is a sophisticated piece of equipment designed for the application of various coatings onto aluminum foil substrates. Understanding its key components is crucial to grasping how this machine operates efficiently. One of the primary components is the unwind section, which holds the raw aluminum foil. This section ensures a steady feed of foil into the machine, preventing unnecessary tensions and wrinkles during the process.

Another critical component is the coating station, where the actual application of the coating takes place. This station often employs specialized rollers or spray nozzles that evenly distribute the desired coating material onto the surface of the foil. The consistency and thickness of the coating can be adjusted based on the end use of the foil, whether it's for packaging, insulation, or other applications. Finally, the drying system plays a pivotal role as it removes any solvents or moisture from the coated foil, solidifying the coating for durability and functionality. Together, these components work harmoniously to produce high-quality coated aluminum foil tailored to various industry needs.

Aluminum foil coating machines are sophisticated pieces of equipment designed to apply a protective or decorative layer to aluminum foil. The process begins with the unwinding of the aluminum foil roll, where the material is loaded onto the machine before going through several crucial steps. First, the foil is cleaned to remove any impurities that might interfere with the coating process. This is typically achieved through a combination of solvent cleaning and mechanical scrubbing, ensuring a pristine surface for optimal adhesion.

Once cleaned, the foil is ready for the application of the coating. The machine utilizes a gravure or roller coating system, which ensures a uniform layer is applied. According to industry reports, the global aluminum foil market was valued at approximately $27 billion in 2021 and is expected to grow at a CAGR of 4.5% between 2022 and 2030, highlighting the increasing demand for quality coatings in packaging and construction applications. After coating, the foil undergoes a drying process, typically achieved through heated air or infrared drying systems, allowing the coating to cure and adhere firmly to the foil before rewinding into rolls for subsequent packaging and distribution.

Throughout this operation, quality control is essential; machines are equipped with sensors and feedback systems that monitor the coating thickness and surface quality. The precision in these steps not only enhances the durability of the product but also maintains the aesthetic qualities that are crucial in consumer markets. As the demand for aluminum foil continues to rise, the efficiency and technology behind these coating machines are likely to evolve, further enhancing production capabilities in this vital industry.

Aluminum foil coating machines play a vital role in various manufacturing processes, particularly in the food packaging and electronics industries. One of the primary benefits of utilizing these machines is their ability to enhance product durability and extend shelf life. According to a report by MarketsandMarkets, the global aluminum foil packaging market is expected to reach USD 37.4 billion by 2025, growing at a CAGR of 4.2%. This growth highlights the increasing demand for efficient aluminum foil solutions, which are made possible through advanced coating technologies.

Additionally, aluminum foil coating machines contribute to sustainability efforts in manufacturing. By enabling the use of thin coatings, they reduce material consumption without compromising the integrity of the product. A study conducted by the Aluminum Association indicates that aluminum can be recycled indefinitely, making it an eco-friendly option for packaging solutions. This efficiency in material use not only lowers production costs but also minimizes environmental impact, aligning with the industry’s move towards more sustainable practices. As manufacturers seek to adopt greener methods, the use of aluminum foil coating machines will likely continue to rise, facilitating innovation and sustainability in production processes across various sectors.