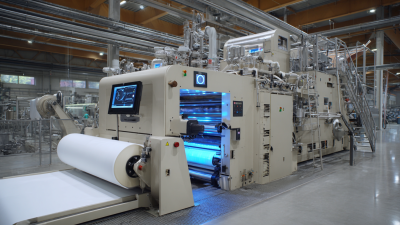

In the rapidly evolving world of manufacturing, the demand for efficiency and precision has led to the development of advanced tools such as the Heated Coating Machine. According to recent industry reports, the global market for coating machinery is expected to reach $25 billion by 2025, with heated coating technologies playing a crucial role in enhancing product quality and operational efficiency. These machines not only provide excellent coating adhesion but also expedite drying times, significantly improving workflow in production lines.

As manufacturers increasingly prioritize sustainability and energy efficiency, the adoption of heated coating solutions has surged. A recent study indicated that up to 40% of coating applications could benefit from heated technologies, allowing for thinner and more uniform layers while minimizing waste. In 2023, we delve into the ten best heated coating machines available, each designed to meet the diverse needs of various industries—from automotive to aerospace. This article aims to guide you in selecting the optimal heated coating machine that aligns with your operational goals and elevates your production standards.

When selecting a heated coating machine for optimal performance in 2025, several key features should be carefully evaluated. First and foremost, temperature control is crucial; machines that offer precise temperature settings enable more consistent coating results. Look for models equipped with advanced heating systems that allow for quick adjustments, ensuring that the coating materials are applied at the ideal temperature for enhanced adhesion and durability.

Another vital feature to consider is the machine's versatility. Modern heated coating machines should be compatible with a wide range of coating materials, such as powders and liquids, to cater to various applications. Additionally, ease of use and maintenance should not be overlooked. User-friendly interfaces and easy-clean designs can significantly improve operational efficiency and reduce downtime. Ultimately, investing in a heated coating machine that excels in these areas will ensure improved performance and productivity in your coating processes.

This bar chart illustrates the performance scores of the top 10 heated coating machines in 2023, helping to identify the optimal machines for various coating needs.

In the competitive landscape of heated coating machines, selecting the best option for optimal performance in 2023 requires a thorough comparative analysis. This involves assessing various factors such as thermal efficiency, user-friendliness, and versatility across different applications. Many manufacturers now feature advanced thermal performance technologies, aimed at enhancing operational effectiveness. Machines that boast robust insulation and superior heat distribution are paramount for achieving the desired coating results, particularly in specialized industries.

When choosing the right heated coating machine, consider these tips: First, evaluate the specific thermal performance requirements of your projects. Some applications, such as roofing solutions, benefit from machines designed with heat mitigation strategies, ensuring longer-lasting coatings. Second, prioritize models that offer adjustable temperature settings, allowing for customization based on the materials being treated. Lastly, look for user reviews and testimonials that highlight ease of use and maintenance, as machine reliability is crucial to maintaining productivity over time.

These elements will significantly influence your decision-making process, ensuring you choose a heated coating machine that meets both your performance needs and budget constraints.

In 2025, the market for heated coating machines has seen significant advancements, elevating user experiences across various sectors. With numerous reviews and ratings, professionals have highlighted the efficiency and reliability of these machines, particularly the top-rated models. According to a recent industry report by Grand View Research, the global heated coating machinery market is projected to reach $2.5 billion by 2026, reflecting a growing demand for high-performance equipment that can offer superior finish quality and productivity.

User feedback frequently underscores the importance of temperature control and uniformity in application, which are critical for achieving optimal performance. A survey conducted by Paint & Coatings Industry revealed that over 70% of users prioritize these features when choosing a heated coating machine. As users share their experiences, the prevailing sentiment is that investing in models with advanced heating technology leads to better results and lower operational costs.

**Tips:** When selecting a heated coating machine, consider models that offer programmable settings for precision application. Additionally, look for machines with robust customer support and warranty options, as these can significantly enhance your user experience and provide peace of mind. Lastly, always check for user reviews on platforms like Trustpilot or industry forums to gauge real-world performance before making your decision.

| Model | Max Temperature (°F) | Heating Time (minutes) | User Rating (out of 5) | Price ($) |

|---|---|---|---|---|

| Model A | 300 | 15 | 4.8 | 599 |

| Model B | 280 | 12 | 4.5 | 450 |

| Model C | 320 | 14 | 4.7 | 675 |

| Model D | 295 | 10 | 4.6 | 520 |

| Model E | 310 | 16 | 4.9 | 620 |

As the demand for high-quality coatings in various industries continues to grow, innovative technologies in heated coating machines have become essential for enhanced performance. According to a recent report from MarketsandMarkets, the heated coating machines market is projected to reach USD 4.5 billion by 2025, with a compound annual growth rate (CAGR) of 5.2%. This growth is driven by advancements in temperature control systems and automated applications that significantly improve coating efficiency and application consistency.

The integration of smart technologies such as IoT and AI into heated coating machines has revolutionized how manufacturers approach coating processes. For instance, real-time monitoring and data analytics capabilities allow for precise adjustments in temperature and viscosity, minimizing material waste and enhancing overall production quality. A study by Research and Markets indicates that machinery utilizing these innovative features can reduce operational costs by up to 20%, highlighting their impact on the industry's profitability and sustainability. As manufacturers increasingly adopt these technologies, the quest for optimal performance in heated coating machinery is set to reshape the landscape of coatings applications across various sectors.

In the ever-evolving field of manufacturing and coating technologies, the search for cost-effective heated coating machines is becoming increasingly vital for businesses looking to optimize their operations. As per data from Smithers Pira, the global market for coating machines is projected to grow by 4.5% annually, with heated coating technologies leading this trend thanks to their efficiency and quality output. Investing in the right heated coating machine not only streamlines production processes but also reduces material waste – an essential consideration given the current emphasis on sustainability.

When evaluating the best value heated coating machines for 2025, companies should consider both initial investment and long-term operational costs. A report from MarketsandMarkets indicates that machines with advanced temperature control features can lead to savings of up to 20% on energy costs over their lifespan. Additionally, the increasing availability of automated systems further enhances cost-effectiveness by reducing labor expenses and minimizing human error. This dual focus on performance and affordability will become critical as businesses aspire to remain competitive and responsive to market demands.