As the demand for electric vehicles and renewable energy storage continues to soar, the role of lithium battery technology becomes increasingly critical. According to a recent report by Allied Market Research, the global lithium-ion battery market is expected to reach USD 151.09 billion by 2025, growing at a compound annual growth rate (CAGR) of 17.5%.

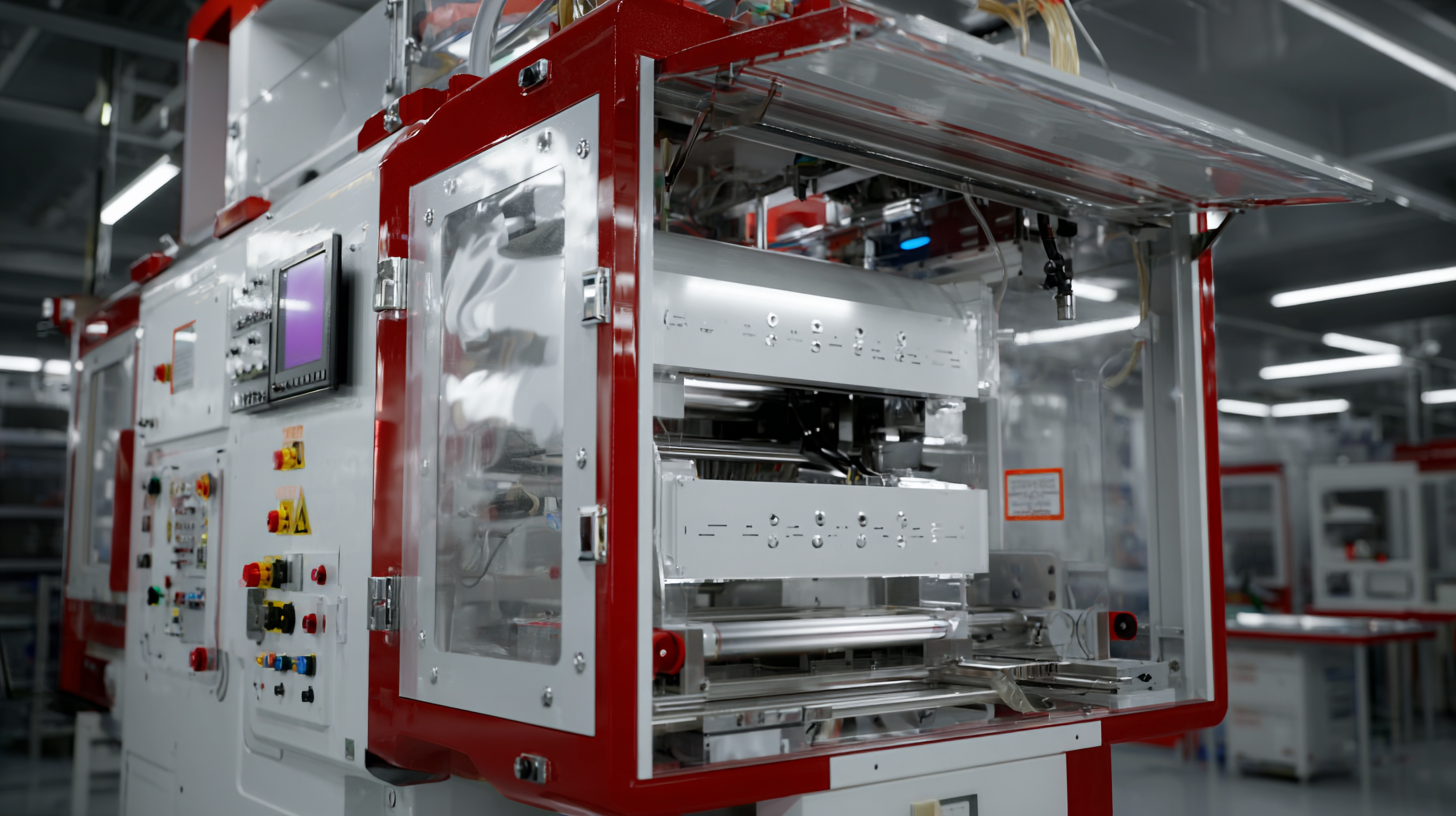

Central to the production of these batteries is the effectiveness of the Lithium Battery Coating Machine, which plays a vital role in achieving optimal performance and efficiency of the battery cells. Innovative advancements in coating technology not only enhance the energy density and longevity of lithium batteries but also contribute to significant cost reductions in manufacturing.

This blog will explore the latest examples of cutting-edge Lithium Battery Coating Machines and their transformative solutions that are shaping the future of battery production.

The lithium battery industry is experiencing rapid advancements in coating technologies, which play a crucial role in enhancing battery performance, safety, and lifespan. According to a recent market report by Grand View Research, the global lithium-ion battery market was valued at approximately $37 billion in 2020, with expectations to grow at a compound annual growth rate (CAGR) of 17.2% from 2021 to 2028. This surge is driving innovation in manufacturing processes, particularly in coating applications, which are vital in determining the electrochemical stability and efficiency of battery cells.

One of the most promising advancements is the development of advanced coating machines that employ techniques such as slot-die coating and spray coating. These methods provide precise control over the thickness and uniformity of the electrode coatings, which is essential for maximizing energy density and ensuring consistent performance. For instance, the use of slot-die coating can reduce material waste by up to 20% compared to traditional coating methods, as stated in a report by IDTechEx. As manufacturers strive for higher production capacities without compromising quality, innovations in coating technology will play a pivotal role in shaping the future of lithium battery production.

Lithium battery coating machines play a crucial role in the production of high-performance batteries, particularly in the rapidly growing electric vehicle (EV) and renewable energy sectors. One of the key features of top-tier lithium battery coating machines is their precision in applying uniform coatings. According to a report by ResearchAndMarkets, the global lithium-ion battery market is expected to reach $105.1 billion by 2025, which underscores the need for advanced manufacturing processes. Machines equipped with technologies like gravure or slot-die coating ensure that the electrode materials receive a consistent and controlled application, significantly enhancing battery efficiency and longevity.

Another important aspect is the automation and intelligence embedded within these machines. Advanced lithium battery coating systems often utilize real-time analytics to monitor and optimize the coating process. A study by Grand View Research highlights that the demand for automated manufacturing processes in battery production is projected to grow at a CAGR of 22.4% from 2022 to 2030. Such features not only improve production rates but also minimize waste, contributing to more sustainable manufacturing practices. These innovations not only boost the overall performance of lithium batteries but also make a significant impact in shaping the future of energy storage solutions.

| Machine Type | Coating Method | Max Coating Width (mm) | Speed (m/min) | Layer Thickness Range (μm) | Drying Method | Control System |

|---|---|---|---|---|---|---|

| Automatic Coating Machine | Slot Die Coating | 1000 | 5 | 1-10 | Infrared Drying | PLC with Touch Screen |

| Batch Coating Machine | Doctor Blade Coating | 800 | 3 | 2-15 | Hot Air Drying | Digital Control |

| Roll-to-Roll Coating Machine | Reverse Roll Coating | 1500 | 10 | 0.5-5 | UV Drying | Computerized System |

| Research Lab Coating System | Air Spray Coating | 300 | 1 | 1-20 | Convection Drying | Manual Control |

In the fast-evolving world of lithium battery production, the efficiency of manufacturing processes is crucial. Chinese lithium battery factories have become frontrunners in adopting innovative coating technologies that significantly enhance production efficiency. By integrating advanced lithium battery coating machines, these factories are able to achieve faster production times while maintaining high-quality standards. This innovation not only accelerates the manufacturing process but also reduces waste, translating to lower operational costs and increased profitability for manufacturers.

The impact of these cutting-edge machines extends beyond mere speed; they also improve the precision of the coating application. Enhanced uniformity in the coating process leads to better battery performance and longevity, which are critical factors for consumers. As competition intensifies in the battery market, leveraging efficient production techniques allows Chinese manufacturers to meet the growing demand for high-performance lithium batteries, particularly for electric vehicles and renewable energy storage solutions. By continuously optimizing their production lines through state-of-the-art technology, these factories solidify their position as leaders in the global battery market.

The thickness of the coating applied to lithium batteries plays a crucial role in determining their overall performance and longevity. Recent studies indicate that an optimal coating thickness can significantly enhance the battery's cycle life and efficiency. For instance, a report from the Journal of Power Sources revealed that a coating thickness in the range of 1-5 micrometers can lead to a 20% increase in capacity retention over 500 charge cycles. This demonstrates the importance of fine-tuning the coating processes used in battery production.

When exploring innovative lithium battery coating machines, it's essential to consider how these machines can achieve precise control over coating thickness. Advanced technologies, such as electrostatic and slot-die coating techniques, allow for consistent application of coatings, ensuring uniformity that can contribute to improved battery performance. Manufacturers that invest in such technologies can expect a competitive edge in the rapidly evolving energy storage market.

Tips: Always monitor the coating uniformity during production; variations can lead to inconsistent battery performance. Additionally, testing different thicknesses in prototype stages can uncover the most suitable balance between capacity and longevity, aiding in the development of next-generation lithium batteries.

The lithium battery coating technology is advancing rapidly, driven by the increasing demand for electric vehicles and renewable energy solutions. According to a recent report by MarketsandMarkets, the global lithium-ion battery market is projected to reach $129.3 billion by 2027, highlighting the critical need for innovative coating solutions. Future trends suggest a shift towards more efficient and eco-friendly materials, such as water-based coatings, which not only enhance performance but also reduce environmental impact.

Tip: When selecting a coating machine, consider its compatibility with various electrode materials. Machines that offer flexible configuration options can adapt to evolving industry standards and customer requirements.

Additionally, automation and AI integration are expected to revolutionize the coating process. A study published by Grand View Research indicates that the incorporation of smart technologies could lead to a productivity increase of up to 25%. As manufacturers prioritize sustainable practices, the push for lower energy consumption during the coating process is also becoming paramount.

Tip: Regular maintenance of your coating machine not only prolongs its lifespan but also ensures consistent quality in the production of lithium batteries. Keeping machinery in optimal condition is key to meeting stringent market demands.