In the rapidly evolving landscape of industrial manufacturing, the demand for advanced machinery has surged, particularly for Heated Coating Machines. According to a recent industry report by Grand View Research, the global market for coating machines is projected to reach $7.8 billion by 2025, with a significant portion driven by innovations in heated coating technologies. However, manufacturers are encountering numerous challenges in adhering to stringent industry standards, which are crucial for product quality and safety. These challenges include maintaining consistent temperature control, ensuring uniform coating application, and complying with environmental regulations. As companies strive to optimize their processes and meet these standards, understanding the intricacies of Heated Coating Machines becomes essential for success in a competitive market.

Adhering to global industry standards for heated coating machines presents a significant challenge for manufacturers aiming to ensure quality and safety. Compliance with these standards often requires meticulous attention to detail in both design and production processes. With variations in regulations across different regions, manufacturers must stay informed about the latest requirements to avoid potential penalties or product recalls.

One effective tip for manufacturers is to invest in training programs for their staff, ensuring they understand the nuances of industry standards. Regular workshops can help employees stay updated on compliance requirements, fostering a culture of quality and diligence. Additionally, engaging with industry experts or consultants can provide invaluable insights into best practices for adhering to these standards.

Another crucial aspect is the implementation of robust quality control measures during the manufacturing process. Monitoring equipment performance and conducting thorough inspections will help identify areas for improvement and mitigate risks associated with non-compliance. By integrating these practices, manufacturers can not only meet industry standards but also enhance customer trust and satisfaction.

The following chart demonstrates the main challenges faced in meeting global industry standards for heated coating machines, including regulatory compliance, technological advancements, and quality assurance.

Consistency and quality control in coating processes are critical to the performance and durability of heated coating machines. However, manufacturers often face hurdles that compromise the integrity of the final product. One major obstacle is the variability in raw materials. Inconsistent quality of coatings can result from differences in chemical formulation and handling. This variability not only affects the coating's performance but also complicates adherence to industry standards.

To combat these challenges, it is essential to implement thorough quality assessments at every stage of production. Regular monitoring of raw materials can help identify discrepancies early, preventing them from affecting the final coating process. Additionally, investing in training for staff can ensure that everyone is equipped with the skills necessary to maintain quality standards.

Another common challenge is the calibration of machinery. Ensuring that heated coating machines operate at the correct temperatures and settings is vital for achieving uniform coatings. Frequent calibration checks and maintenance schedules are critical in preventing machine malfunctions that could lead to quality inconsistencies. Emphasizing these practices can significantly enhance the reliability of coating processes while helping manufacturers meet stringent industry standards.

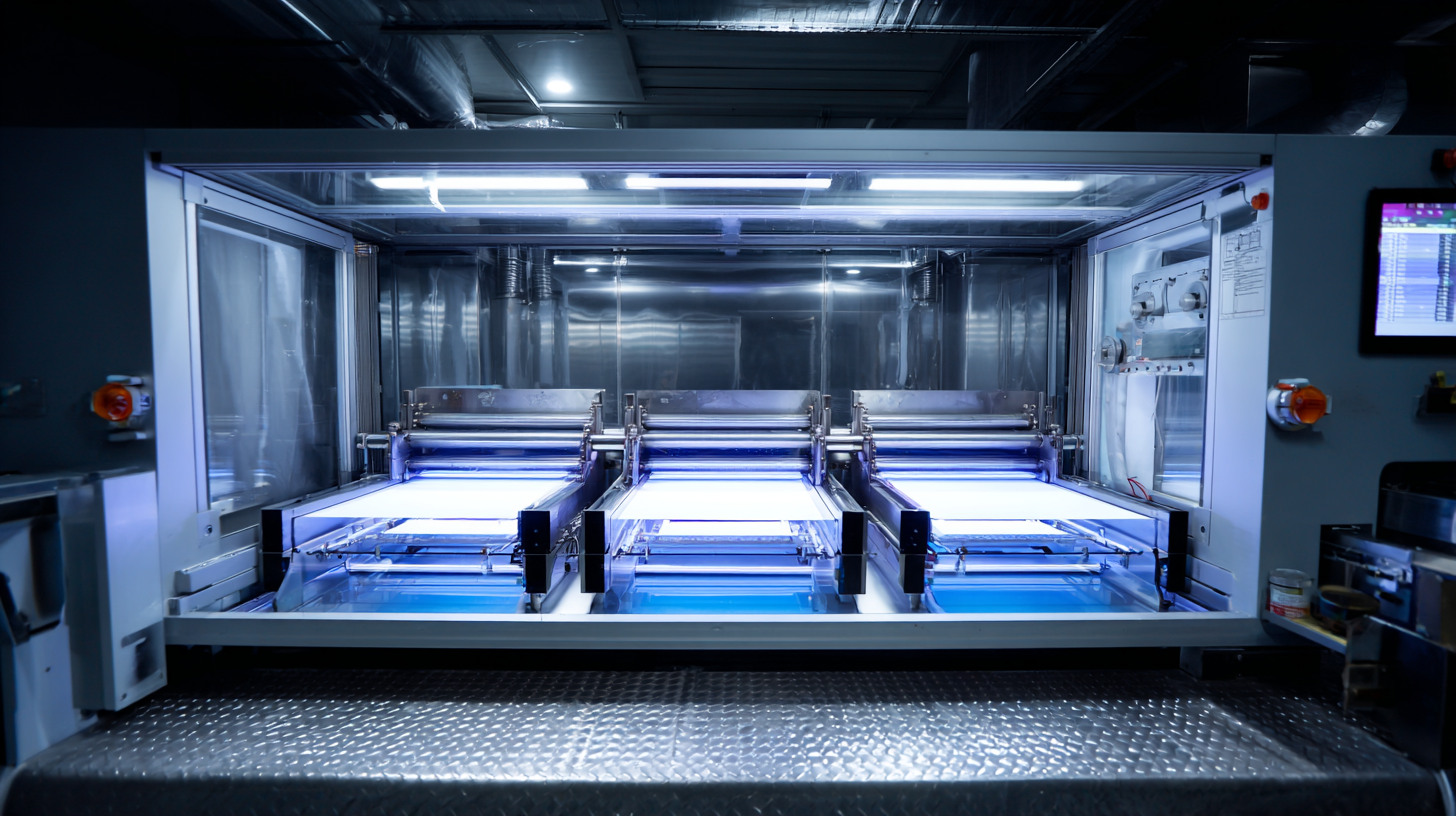

The heated coating industry has experienced remarkable technological advancements in recent years, significantly enhancing equipment performance. These innovations have led to the development of machines that incorporate features such as precise temperature control, improved material compatibility, and greater energy efficiency. Such progress allows manufacturers to achieve more uniform coating applications, which is critical for meeting stringent industry standards. Enhanced performance capabilities also enable quicker production cycles, ultimately benefiting businesses that strive to keep up with the fast-paced market demands.

Furthermore, the integration of smart technologies, like IoT and AI, in heated coating equipment has revolutionized operational efficiency. These technologies facilitate real-time monitoring and predictive maintenance, helping to identify potential performance issues before they arise. Consequently, this not only reduces downtime but also prolongs the lifespan of the machines. As the industry continues to adopt these cutting-edge technologies, companies that embrace innovation will find themselves better equipped to navigate the challenges of meeting and exceeding industry standards, positioning them for sustained success in a competitive landscape.

Meeting safety and environmental standards in manufacturing heated coating machines poses significant challenges for industry players. According to a report by the Global Safety and Health Association, nearly 60% of manufacturers struggle with regulatory compliance due to constantly evolving environmental laws and safety protocols. This is particularly pertinent as industries must adhere to the ISO 9001 standards, which focus on quality management systems, and ensure that their products meet stringent safety regulations. Given the complex nature of these requirements, companies must remain vigilant and proactive in addressing these compliance issues.

Meeting safety and environmental standards in manufacturing heated coating machines poses significant challenges for industry players. According to a report by the Global Safety and Health Association, nearly 60% of manufacturers struggle with regulatory compliance due to constantly evolving environmental laws and safety protocols. This is particularly pertinent as industries must adhere to the ISO 9001 standards, which focus on quality management systems, and ensure that their products meet stringent safety regulations. Given the complex nature of these requirements, companies must remain vigilant and proactive in addressing these compliance issues.

One effective strategy for manufacturers is to invest in comprehensive training for their employees on regulatory frameworks and best practices in safety. Regular workshops can help in keeping the workforce informed about the latest industry standards. Additionally, conducting regular audits of manufacturing processes can significantly enhance compliance and reveal potential areas for improvement.

Another tip is to incorporate advanced technologies that monitor compliance in real time. Utilizing IoT devices can help track emissions and ensure that safety measures are consistently met. A 2022 industry report highlighted that companies adopting such technologies have seen a 30% reduction in compliance-related discrepancies, leading to enhanced operational efficiency and reduced regulatory penalties.

In the quest for meeting industry standards for heated coating machines, enhancing efficiency while minimizing waste in coating production processes is essential. A key strategy is to implement lean manufacturing principles, which focus on reducing non-value-added activities. Regularly analyzing the workflow can help identify bottlenecks in the production line, allowing for optimized operations that streamline processes and reduce excess material usage.

Tips: Conduct regular training sessions for staff to ensure everyone is on board with best practices in waste reduction and efficiency maximization. This knowledge transfer can often lead to innovative solutions being identified from the ground level.

Additionally, investing in advanced monitoring technologies can aid in real-time tracking of coating quality and thickness. This proactive approach not only helps in maintaining high standards but also minimizes defective products, thereby reducing waste. By adjusting machinery settings dynamically based on monitored data, companies can ensure that only the required amount of coating is applied, further decreasing unnecessary expenditure.

Tips: Schedule routine maintenance for machinery to ensure optimal functioning, thereby preventing waste associated with breakdowns and inefficiencies in the coating process.

| Challenge | Impact | Strategy for Improvement | Expected Outcome |

|---|---|---|---|

| Inconsistent Coating Thickness | Increased waste and rework time | Implement advanced measuring systems (e.g., laser measurement) | Improved quality and reduced waste |

| Equipment Downtime | Reduced productivity | Regular maintenance and staff training programs | Higher operational availability |

| High Material Waste | Increased costs | Optimize raw material usage and recycling | Cost savings and environmental benefits |

| Compliance with Regulatory Standards | Legal penalties and brand damage | Stay updated on regulations and conduct regular audits | Avoidance of penalties and improved reputation |