In an era where quality and precision are paramount, selecting the right UV Coating Machine is a crucial decision for businesses aiming to enhance their production capabilities. As the demand for high-performance coating solutions grows globally, it becomes essential to focus on factors such as reliability, efficiency, and technological advancements.

With China's commitment to excellence in manufacturing, it is no surprise that many leading UV coating machines are produced there, offering innovative features that set them apart in the global market. This ultimate checklist serves as a guide for manufacturers and entrepreneurs looking to invest in the best UV Coating Machine, ensuring they make informed decisions that align with their production goals and standards of quality.

Whether you are seeking to boost your operational productivity or improve the finish of your products, understanding the key aspects of UV coating technology will help you navigate the options available and find the perfect fit for your business needs.

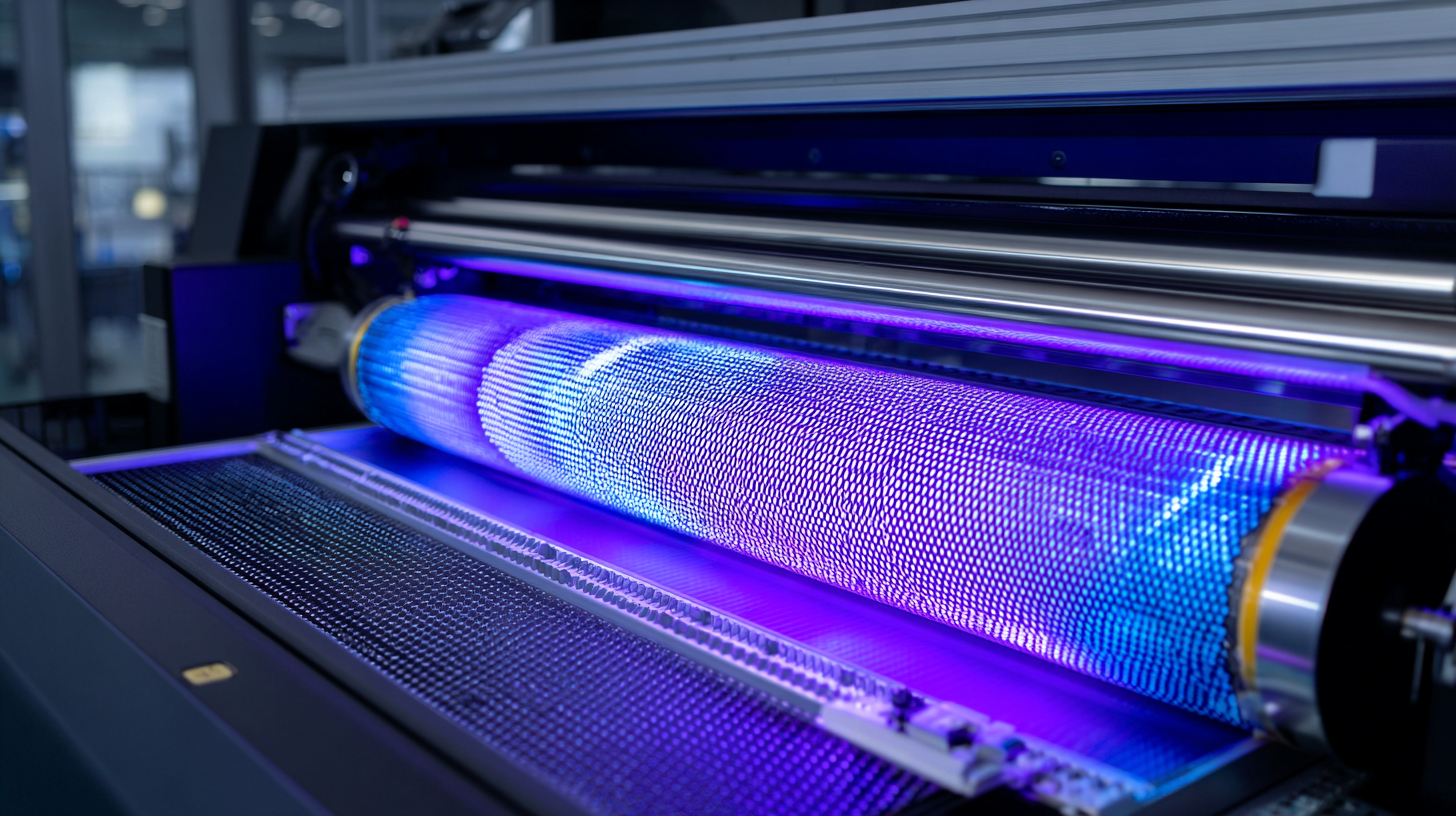

When selecting the right UV coating machine, it's essential to consider several key features that can significantly affect the efficiency and quality of your coating process. One of the primary factors is the machine’s compatibility with various substrates. Whether you're working with paper, plastic, or metal, ensuring that your UV coating machine can handle different materials without compromising the finish is crucial. Additionally, look for machines that provide flexible application methods, such as roller or spray coating, enabling you to adapt your production line to meet diverse customer needs.

Another important feature to evaluate is the curing system. The effectiveness of UV light sources, including their intensity and wavelength, plays a vital role in achieving a durable and high-quality finish. Machines equipped with adjustable UV lamps can offer better control over the curing process, allowing for customization based on the specific coating materials used. Furthermore, the availability of energy-efficient options is becoming increasingly relevant, as it impacts both operational costs and environmental sustainability. By focusing on these key features—substrate compatibility and curing efficiency—you can ensure that your chosen UV coating machine meets your production demands effectively.

When selecting a UV coating machine, understanding the different types of UV coating technologies is paramount. Broadly, UV coating systems can be categorized into several types: traditional UV, LED UV, and hybrid systems. According to a report by Smithers, the global UV coatings market was valued at approximately $4.3 billion in 2021 and is expected to reach $6.2 billion by 2026, driven by the adoption of more environmentally friendly technologies like LED UV.

Traditional UV coatings utilize mercury-based lamps to cure the coating, providing a high-gloss finish but often requiring more energy and longer curing times. In contrast, LED UV technology has gained traction due to its quicker curing times and reduced energy consumption, promoting sustainability in industries. A study by the Future Market Insights emphasizes that LED UV technology is projected to grow at a CAGR of 12.5% from 2021 to 2031, indicating its rising popularity due to efficiency and lower heat emission, which is crucial for substrates sensitive to heat.

Hybrid systems, which combine both traditional and LED technologies, are also becoming increasingly common. They offer versatility by allowing producers to switch between curing methods depending on the material used and desired finish. This flexibility is essential in industries that handle a wide range of substrates. Understanding these technologies not only influences the choice of UV coating machine but also impacts production efficiency and environmental compliance.

When selecting a UV coating machine, understanding the factors that affect its cost is crucial. According to a recent industry report by Freedonia Group, the market for UV coating machines is projected to grow significantly, driven by advancements in technology and increasing demand for high-quality finishing. The report highlights that the price range for UV coating machines can vary widely, from $15,000 to over $100,000, influenced by features such as automation level, speed, and print size capabilities.

One major factor impacting cost is the machine's technological sophistication. High-end machines equipped with advanced automation and faster curing capabilities generally come with a higher price tag. For example, fully automated UV coating machines can cost up to 50% more than semi-automatic models, as reported by Technavio. Additionally, the type of coating materials and their compatibility with specific machines can also affect overall expenses. As the industry shifts towards more eco-friendly and versatile coatings, manufacturers must balance initial investments with long-term operational costs, making comprehensive cost analysis essential for informed purchasing decisions.

When investing in UV coating equipment, maintenance is crucial to ensure optimal performance and longevity. According to a 2022 industry report by Smithers, regular maintenance can extend the lifespan of UV machines by up to 30%, reducing operational costs significantly.

Proper cleaning of the UV lamp and optical components not only enhances curing efficiency but also prevents costly downtime. It's essential to develop a structured maintenance schedule that incorporates routine inspections and immediate corrective actions to mitigate wear and tear.

Furthermore, staying updated on the latest advancements in UV technology is vital. The same Smithers report highlights that advancements in UV coatings have improved durability and sustainability, which can affect maintenance needs. For instance, newer coatings often require less frequent adjustments and cleaning, thus saving time and labor.

Operator training is also a key component; well-trained staff can identify issues early, maintain optimal settings, and adhere to best practices. Therefore, investing in both equipment and training will contribute to a more efficient and cost-effective UV coating operation.

When it comes to selecting the right UV coating machine, understanding the landscape of popular brands and their offerings is essential. According to a recent industry report by Smithers Pira, the global UV coatings market is projected to grow at a compound annual growth rate (CAGR) of 7.5%, reaching $5.6 billion by 2025. This growth underscores the importance of choosing a machine that not only meets your current needs but also adapts to future industry trends.

Among the standout brands, companies like Rigoli, Kluge, and Roland have consistently received high marks for their innovative technology and reliability. Rigoli, for example, is noted for its efficient processing capabilities that can significantly reduce production time while maintaining quality. In contrast, Kluge's legacy in UV coating machines emphasizes durability and long service life, making them a favorite among high-volume production facilities. Meanwhile, Roland offers user-friendly interfaces that cater to smaller operations, supporting various substrates in UV printing. Each of these brands has tailored their offerings to appeal to different segments of the market, showcasing the versatility and adaptability required in today’s printing and manufacturing environments.