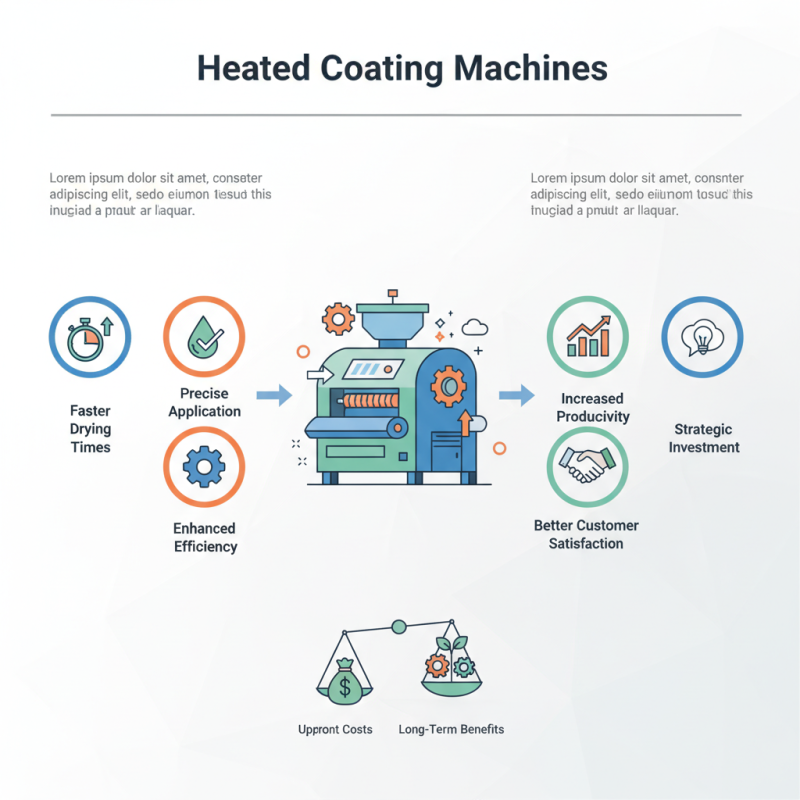

In today's competitive market, investing in a Heated Coating Machine can significantly enhance efficiency. According to industry expert John Anderson, "The right equipment can change the game for businesses." A Heated Coating Machine can offer precise application and faster drying times, vital for maintaining productivity.

Many businesses are transforming their operational strategies. These machines provide solutions not only for coatings but also for various surface treatments. Yet, some businesses hesitate, questioning the upfront costs versus long-term benefits. Understanding the true value of a Heated Coating Machine requires careful consideration.

Efficiency is crucial, but so is the quality of the output. Balancing both can lead to better customer satisfaction. While the benefits are clear, it’s essential to reflect on whether the investment aligns with your business goals. This journey toward modernization deserves introspection.

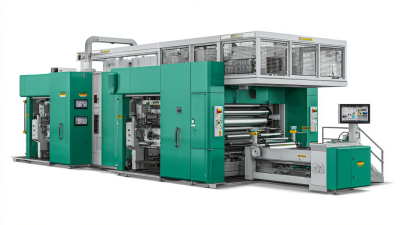

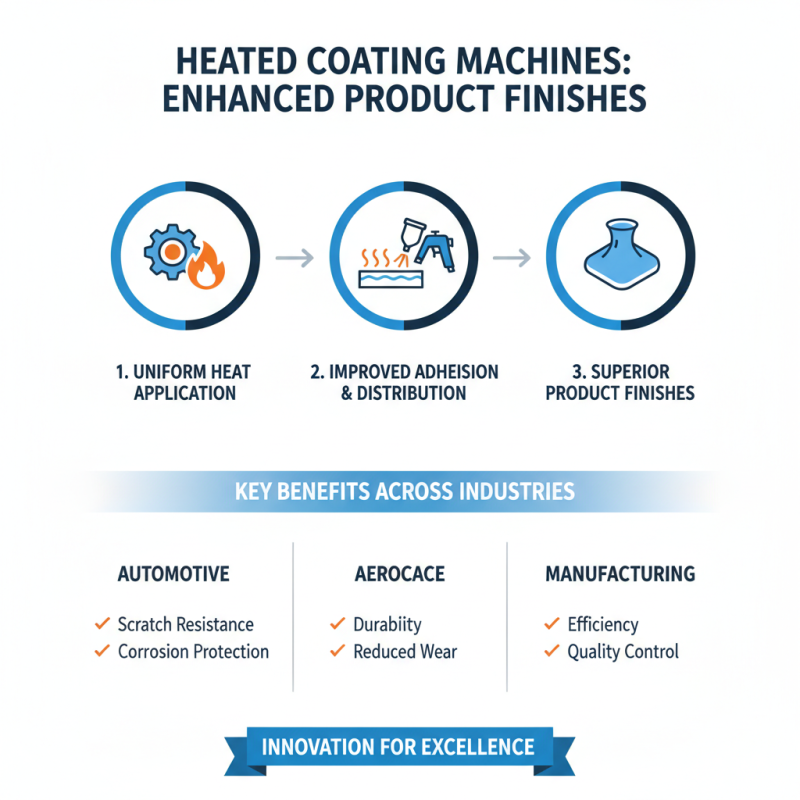

Heated coating machines are gaining popularity in various industries. They operate by applying heat to coatings, ensuring even distribution and better adhesion. This technology allows businesses to enhance their product finishes significantly.

Using a heated coating machine can reduce application time. The heat helps coatings dry faster, resulting in increased productivity. However, controlling the temperature is essential. If it's too hot, the coating may bubble or crack. Finding the right balance is a challenge that many operators face.

Proper maintenance of these machines is vital. Regular checks can prevent malfunctions, ensuring consistent results. Some users report difficulties in achieving uniform heating across larger surfaces. Testing different techniques can lead to improvements. Adjusting settings may yield better outcomes, but it requires patience and careful observation.

Heated coating machines bring numerous benefits to businesses. They enhance the quality of coatings, ensuring a smoother finish. This is especially important in industries like automotive and electronics. A heated machine can speed up the curing process, allowing for faster production cycles. More efficiency often leads to increased output.

These machines also improve adhesion for various materials. Heat helps the coating stick better, reducing the chance of defects. However, businesses should consider their specific needs. Not every operation may benefit equally from heated technology. Some may find initial costs too high.

Additionally, while heated coating machines can boost performance, they require regular maintenance. Overlooking upkeep could lead to inconsistencies in quality. Training staff on proper usage is vital and can be a challenge. The transition to heated systems might involve a learning curve that some teams struggle with.

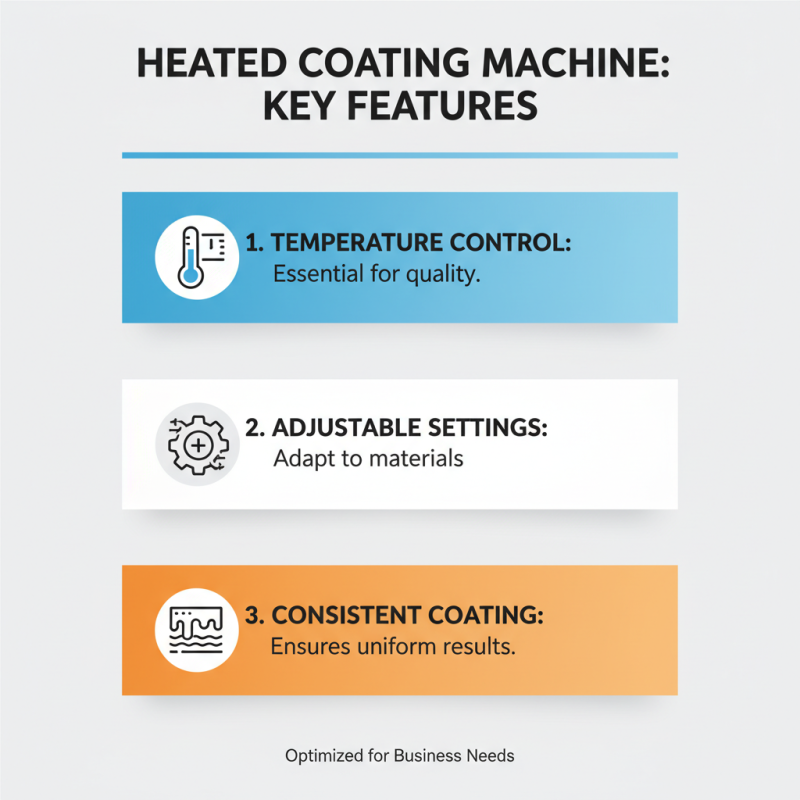

When considering a heated coating machine, focus on key features that matter most to your business. Temperature control is essential. Precise heating ensures consistent coating quality. Look for machines with adjustable settings. This flexibility allows you to adapt to different materials and processes.

Another important feature is the ease of use. User-friendly interfaces can significantly reduce training time. Operators should feel comfortable handling the machine. Complex controls can lead to mistakes. Also, consider the machine's maintenance requirements. Regular upkeep is necessary. Machines that are hard to maintain can become a burden over time.

Durability is crucial, yet often overlooked. A robust design withstands daily use. Evaluate the materials used in construction. Cheaper components might save money initially but can cause long-term issues. Reflecting on these aspects will help ensure you make a well-informed choice for your business's specific needs.

Heated coating machines serve various industries effectively. These machines apply thermal coatings, enhancing durability and performance. Industries like automotive, aerospace, and electronics find them especially useful. They protect parts from wear and corrosion, extending their lifespan.

In the automotive sector, heated coatings are essential. They improve the durability of engine components and exterior surfaces. Aerospace companies use these machines for intricate parts that face extreme conditions. Heated coatings provide necessary protection against high temperatures and pressure.

Tips: Regular maintenance is crucial. Ensure your machine operates efficiently. Check temperature settings to avoid under or over-heating. Always use suitable coatings for specific materials.

Electronics also benefit greatly. Heated coating machines enhance circuit board protection against moisture. They improve performance and reduce failures. Yet, improper application can lead to defects. This is a challenge many businesses face. Understanding the material compatibility is vital.

When considering a heated coating machine for your business,

cost-effectiveness is key. These machines can boost productivity. They reduce energy use and material waste.

In the long run, they pay for themselves. Saving on costs allows for reinvestment into other areas.

This leads to growth and innovation.

Tips for choosing the right machine include assessing your production volume.

If your needs change frequently, flexibility is vital.

Invest in a machine that can adapt. Research energy efficiency ratings.

An efficient machine lowers your bills and contributes to sustainability.

Remember that initial costs can seem high. However, the return on investment often outweighs this.

Analyze your expected output and schedule. A well-chosen heated coating machine can enhance workflow.

Evaluate your options, but don't get lost in details. Focus on your unique business needs

and make a thoughtful decision.