In recent years, the demand for sustainable energy solutions has grown tremendously. According to the International Energy Agency, hydrogen production could increase by over 400% by 2030. One key innovation driving this change is the Hydrogen Fuel Coating Machine. This technology enhances the efficiency of hydrogen applications, making it a vital asset for businesses aiming to invest in clean energy.

Dr. Emily Carter, a leading expert in hydrogen technologies, emphasizes the importance of this equipment: "Hydrogen Fuel Coating Machines can redefine how we approach energy efficiency." This machine not only increases productivity but also aids in reducing harmful emissions. Companies that have adopted this technology report a significant decrease in energy costs.

Challenges do remain. Not all industries have adapted quickly to this transformative technology. Some businesses hesitate due to initial investment concerns. However, the long-term benefits often outweigh these initial hurdles. Those who take the leap into using a Hydrogen Fuel Coating Machine may find themselves at the forefront of a rapidly evolving market, shaping the future of energy.

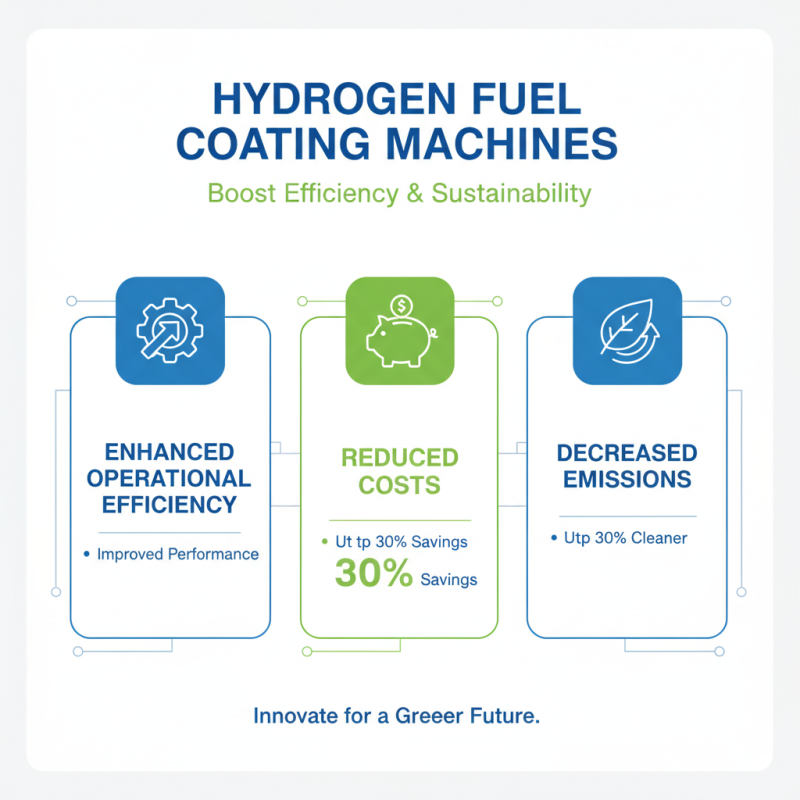

In recent years, hydrogen fuel coating machines have gained attention in various industries. These machines offer notable advantages that can enhance operational efficiency and reduce costs. Studies indicate that businesses using hydrogen fuel technology can decrease emissions by up to 30%. This reduction is significant for companies aiming for sustainability.

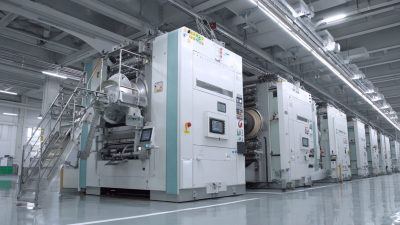

Moreover, hydrogen fuel coating machines can operate at high speeds. They provide faster production rates compared to traditional methods. A report from an industry insight group shows that efficiency can increase by 25% in coating applications. This translates into shorter lead times and improved competitiveness. However, the initial investment in equipment can be a barrier. Businesses must consider the long-term savings against these upfront costs.

Additionally, maintenance is a crucial factor. Hydrogen fuel systems can require specialized knowledge for upkeep. Reports suggest that companies often face challenges in training staff. The reliability of equipment can vary, impacting overall production. Therefore, businesses should evaluate these factors thoroughly before adopting this technology. The potential benefits are clear, but the execution must be carefully planned.

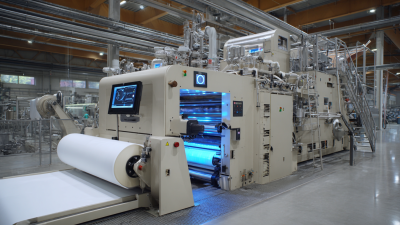

Hydrogen fuel coating machines are revolutionizing the manufacturing landscape. They enhance efficiency in several significant ways. In a recent study, companies using these machines reported a 40% increase in coating application speed. This means less downtime and quicker production cycles.

Moreover, the precision offered by hydrogen fuel technology leads to reduced material waste. According to industry data, businesses utilizing these machines saw a 30% decrease in wasted resources. This not only saves costs but contributes to sustainability efforts as well.

However, transitioning to hydrogen fuel technology is not without its challenges. Initial setup costs can be high, and staff training is crucial. Some companies may find the learning curve steep. It is important to reflect on these potential hurdles while considering the long-term benefits. Balancing immediate expenses against future savings is key to a successful implementation.

When selecting a hydrogen fuel coating machine, consider key features that enhance performance and efficiency. Precision is crucial; look for machines that offer exact control over coating thickness. According to industry reports, a 20-micron variation in thickness can significantly impact fuel efficiency and performance. Machines with advanced sensors can help maintain this precision throughout the coating process.

Efficiency also matters. Coating machines equipped with high-speed application technology can reduce production time by up to 30%. Fast workflows increase productivity, allowing businesses to meet growing demands. Automated cleaning systems can minimize downtime and maintenance efforts, contributing to overall operational efficiency.

Cost-effectiveness is another vital aspect. While advanced machines might require a higher initial investment, reports suggest they pay for themselves within a few years through reduced operational costs. However, not all machines are created equal. Research indicates that businesses sometimes overlook energy consumption rates, which can add to long-term costs. Understanding these numbers is essential for making an informed decision.

Hydrogen fuel coating machines offer a modern alternative to traditional coating methods. Traditional coatings often rely on solvent-based materials. These can emit harmful VOCs, which impact air quality. In contrast, hydrogen fuel coatings are cleaner. They can reduce VOC emissions by up to 90%, according to recent studies.

Efficiency is another critical factor. Traditional methods can take hours or days to achieve the desired finish. Hydrogen fuel technology allows for rapid application. Reports show that turnaround times can improve by as much as 50%. This efficiency can lead to significant cost savings over time. Furthermore, the durability of hydrogen coatings often surpasses that of conventional options.

However, challenges exist. Initial investment costs for hydrogen machines may be higher than traditional methods. Training staff to use this technology effectively could also pose difficulties. Additionally, market adoption is still growing. Some businesses may hesitate due to the lack of widespread acceptance. Despite these hurdles, the advantages of hydrogen fuel coatings are compelling. They promise not only sustainability but also competitive edge.

Hydrogen fuel coating machines offer significant long-term cost savings for businesses. By utilizing hydrogen, companies can achieve efficient energy use in their coating processes. This efficiency often translates directly into reduced production costs. Many businesses find that initial investments lead to savings on energy bills and materials over time.

The environmental impact of hydrogen fuel technology is noteworthy. Hydrogen is a clean energy source. It produces only water vapor as a byproduct during combustion. This characteristic can drastically reduce harmful emissions compared to traditional coatings. However, some challenges exist. The production and storage of hydrogen can be complex. Businesses must consider these factors when integrating this technology.

Transitioning to a hydrogen fuel coating machine may require thoughtful planning. Some companies underestimate the learning curve in implementing new processes. Staff training and equipment adjustments are necessary. A cautious approach can turn these hurdles into opportunities for growth. Embracing this technology not only benefits the bottom line but also supports a sustainable future.