In today's highly competitive manufacturing landscape, selecting the appropriate Customizable Coating Machine is crucial for enhancing product quality and production efficiency. According to a recent industry report by MarketsandMarkets, the global market for coating machines is projected to reach $8.5 billion by 2025, growing at a CAGR of 5.1%. As businesses strive to meet diverse client demands and regulatory standards, the ability to customize coating applications becomes increasingly vital.

This demand for versatile and efficient coating solutions is evident across various sectors, including automotive, electronics, and food packaging. By understanding the specific needs of your operations and aligning them with technological advancements, choosing the right Customizable Coating Machine can significantly streamline processes, reduce waste, and improve overall profitability.

Identifying your business requirements for a coating machine is crucial to making an informed purchase that enhances your production capabilities. Begin by assessing the specific applications your business requires. Consider the types of products you will be coating and the materials involved. Different coating machines offer various functionalities, such as powder coating, liquid coating, or even specialty coatings, each suitable for different industries like automotive, electronics, or furniture manufacturing. Understanding your product specifics will help narrow down the options that align with your operational needs.

Additionally, evaluate the production volume and frequency at which you will use the coating machine. High-volume operations may benefit from machines with quick changeover times and automation features, enabling efficient scaling and reduced downtime. Conversely, smaller businesses or niche markets may prioritize versatility or cost-effectiveness over production speed. Another important factor is the available space in your facility—ensure that the machine dimensions fit comfortably within your layout, allowing for proper ventilation and ease of operation. By meticulously identifying these requirements, you can select a coating machine that not only meets your immediate needs but also supports your business growth in the long run.

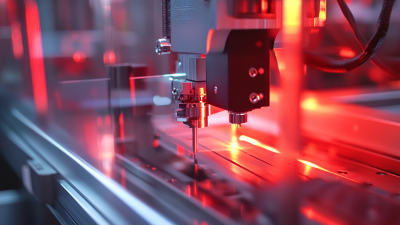

When selecting a customizable coating machine for your business, it's essential to first understand the various types available in the market. Generally, coating machines can be grouped into several categories based on their application and functionality. Common types include rotary coaters, fluidized bed coaters, and spray coaters. Each of these machines offers unique features tailored to specific coating processes, making it crucial to assess which type aligns best with your production needs.

Rotary coaters are ideal for applying a uniform coating over various substrates and are particularly favored in the pharmaceutical and food industries. In contrast, fluidized bed coaters provide efficient coating by suspending particles in a fluid-like environment, ensuring even application and increased efficiency. Spray coaters, on the other hand, utilize a spray mechanism to deliver precise amounts of coating, offering versatility for both small and large batches. Understanding these different types will help in selecting the right customizable coating machine tailored to your business requirements, ultimately enhancing productivity and product quality.

When selecting a customizable coating machine, evaluating key features that impact performance and efficiency is crucial. First and foremost, consider the machine's application versatility. A machine capable of handling various coating materials and processes will save you time and increase productivity. Look for options that offer quick changeover capabilities to adapt to different projects seamlessly.

Another vital feature to assess is the machine's automation level. Advanced automation can significantly enhance efficiency by reducing manual labor, improving consistency, and minimizing errors. Additionally, features like real-time monitoring systems can provide valuable insights into production performance, allowing for quicker decision-making and adjustments as needed.

Tips: When assessing a coating machine, always request a demo to evaluate its ease of use and performance firsthand. Check for customer reviews and case studies to gain insights into real-world performance. Finally, consider the energy efficiency of the machine; opting for energy-saving features can lead to lower operating costs in the long run.

When selecting a customizable coating machine, it's essential to assess your budget constraints carefully. The initial cost of the equipment can vary significantly based on features, capacity, and technological advancements. Businesses must determine how much they can realistically invest without compromising other operational needs. This initial assessment should also consider the potential financing options available, which can ease the immediate financial burden while allowing access to higher quality machinery that meets specific production requirements.

Long-term cost considerations are equally critical in this decision-making process. Beyond the initial purchase, businesses should evaluate operating costs, including maintenance, energy consumption, and the cost of consumables. Investing in a more efficient machine might entail a higher upfront cost, but it can result in lower long-term operational expenses. Furthermore, consider the expected lifespan of the equipment and potential resale value. By balancing these budgetary constraints with projected costs over the life of the machine, companies can make a more informed decision that aligns with their financial goals and operational efficiency.

When choosing a customizable coating machine, researching suppliers should be your first step. Conduct thorough research to identify manufacturers known for their reliability and quality. Look for reviews and testimonials from other businesses that have used these machines. This will give you insight into the experiences of other customers and help you assess the reputation of various suppliers. Don't hesitate to reach out to suppliers with specific questions about their products, as well as their capabilities for customization to meet your unique business needs.

Understanding support options is equally important. A good supplier will offer comprehensive support services, including installation, training, and maintenance. Inquire about the types of training provided to ensure your team can operate the machinery efficiently. Additionally, check if the supplier offers ongoing technical support and how easily accessible their customer service is. Having a reliable support system in place can significantly reduce downtime and ensure that your coating process runs smoothly. Prioritize suppliers who demonstrate commitment to customer service, as this can greatly enhance your operational efficiency in the long term.