Choosing the right Paper Coating Machine is crucial for any printing business. This decision impacts quality and efficiency. With numerous options available, it can be overwhelming. Key factors must be considered when making your selection.

Firstly, think about your specific needs. Different machines offer distinct features. Some are better for thicker papers, while others excel with lighter materials. Next, consider production volume. A high-capacity machine may be necessary for larger operations. However, smaller businesses might not require such power.

Cost is another important factor. Balance your budget with quality. Investing in a reliable Paper Coating Machine can save money in the long run. Always review potential suppliers. Check their reputation and service support. Take your time to evaluate all options carefully. This choice should align with your business goals. Remember, the right machine can enhance your operations significantly.

When selecting a paper coating machine, several key factors should guide your decision. Capacity is crucial. Determine your production volume. A machine with insufficient capacity will lead to bottlenecks. Consider the type of coatings you plan to use. Different machines handle various formulations. If you're looking at specialty coatings, ensure compatibility.

Another critical factor is the machine's speed. Faster machines can increase efficiency, but they might compromise quality. Balancing speed with quality is essential. User-friendliness is also vital. Complex machines can slow down training for new operators. Make sure the interface is intuitive.

Don't overlook maintenance needs. Machines that are harder to service can lead to delays. Check the availability of parts and service. Think about the long-term costs too. A cheaper machine might require more frequent repairs. Reflect on your specific needs before making a choice.

Choosing the right paper coating machine involves understanding the types of technologies available. Different coating methods suit various production needs and print qualities. For instance, gravure coating delivers high precision for intricate designs. A study by Smithers Pira indicates that this method is gaining popularity, projected to grow at a rate of 6.5% annually.

Another common type is roller coating. This approach is efficient for high volume runs. It uses a smooth application process that reduces waste. However, users often overlook maintenance needs. An industry report noted that poorly maintained machines could lead to inconsistent results. Such outcomes often reflect the quality of the final product.

Film coating technology is another viable option. It enhances durability and moisture resistance. Yet, not all setups are equipped for film coating. Proper training and knowledge of machine capabilities are crucial. Many operators face challenges with coating uniformity. Research suggests investing in training programs can mitigate these issues. Understanding these technologies is key in selecting the right machine for your specific needs.

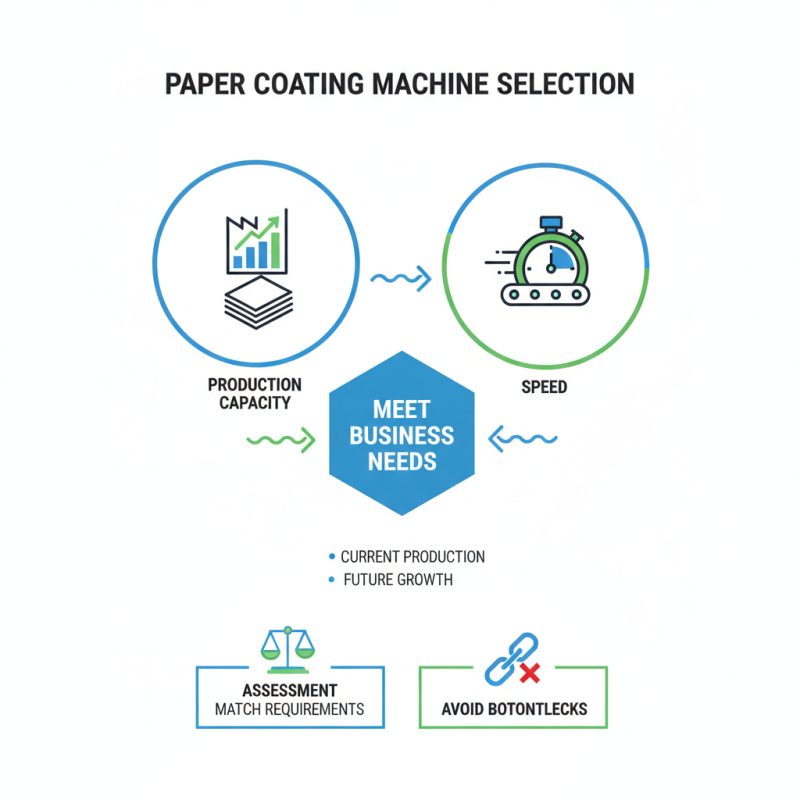

When selecting a paper coating machine, production capacity and speed are crucial. Assessing these factors ensures the machine meets your business needs. Consider your current production levels. Are you looking to maintain or increase output? Matching the machine’s capacity with your requirements is essential to avoid bottlenecks.

Speed is another significant aspect. A faster machine can boost production rates, but that might come at a cost. Ensure the speed aligns with your workflow. High speed doesn’t always equal better quality. You may need to compromise. Sometimes, reliability matters more than speed.

**Tips:** Always analyze your daily production needs. If your volumes fluctuate, consider a flexible machine. Invest in a piece of equipment that grows with you. Test various options. It’s okay if things don’t work out immediately. Learning from these experiences can lead to better choices in the future. Always have backup plans; they safeguard against unexpected demands.

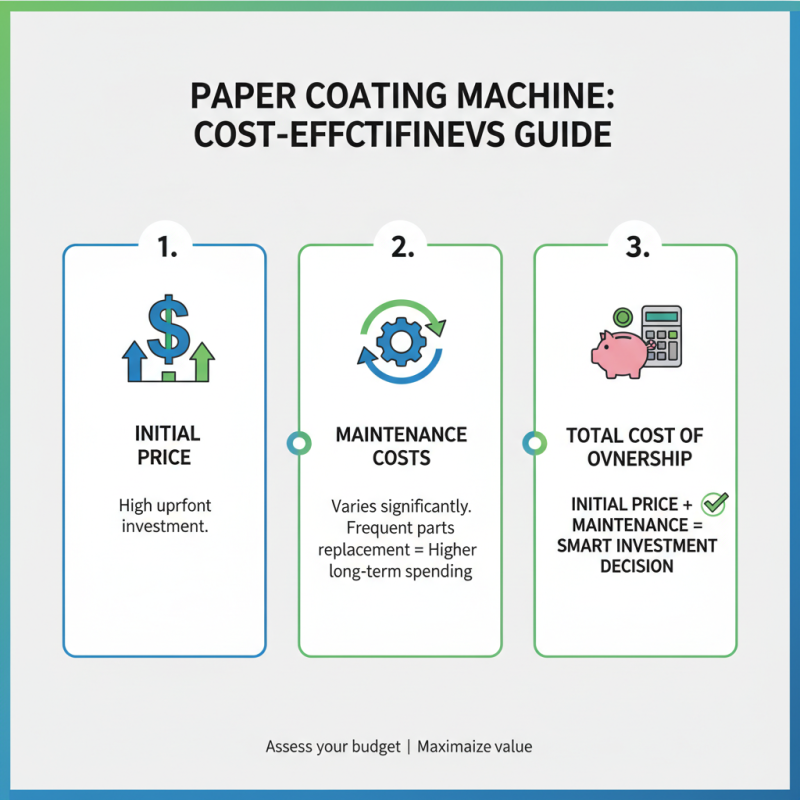

When selecting a paper coating machine, cost-effectiveness should be a major consideration. Many machines come with a high initial price. Yet, maintenance costs can vary significantly. Some models require frequent part replacements, leading to increased spending over time. Users must assess these costs in relation to their budget. Knowing the total cost of ownership is vital for smart investment.

Maintenance can be a double-edged sword. Simple machines may seem cheaper initially. However, they could face breakdowns more often. On the other hand, advanced machines may demand a higher upfront cost. Yet, they often offer better reliability and require less frequent repairs. Consider the skill level of your team as well. A complicated machine may not be ideal if your staff lacks experience.

Take time to think about your specific needs. Different industries may prioritize different features. For instance, a printer might need precise coating options. Meanwhile, packaging businesses may focus on efficiency. Testing various machines can reveal their strengths and weaknesses. You might find that what seems perfect on paper isn’t as effective in practice.

Choosing the right paper coating machine hinges on understanding key features and specifications. One critical element is the coating method. Machines can use techniques like roll-to-roll or sheet-fed processes. Each method has its advantages, impacting production speed and quality. According to a market report, 45% of manufacturers prefer roll-to-roll for high-volume production due to efficiency.

Another important specification is the machine's capacity. Production needs vary widely. A machine capable of processing up to 1,500 sheets per hour may suffice for small operations. In contrast, larger businesses might need up to 5,000 sheets per hour. This disparity illustrates the importance of assessing current and future production goals.

Operators must also consider flexibility and adaptability. The ability to change coating materials and adjust settings is vital. Markets shift rapidly, requiring machines that can keep pace. A report indicates that 60% of users express dissatisfaction with a lack of adaptability in their current machines. They frequently face challenges when trying to meet diverse client needs. Understanding these specifications can guide better decision-making and help avoid costly missteps.