Choosing the right film coating machine is crucial for your production needs. According to industry expert Dr. Jane Smith, “The right machine can significantly enhance product quality and efficiency.” With various options available, selecting the appropriate one might seem overwhelming.

Different types of film coating machines serve different purposes. Some are designed for specific industries, while others offer versatility. It is important to consider the technical specifications, such as coating thickness and application methods. Your production volume will also play a role. A small scaler might not need the same capacity as a large manufacturer.

Reflecting on your specific requirements is essential. Consider the materials you will be working with. Test runs may be necessary to ensure the machine meets your expectations. Making a choice without thorough research could lead to inefficiencies. In the fast-paced world of manufacturing, the right film coating machine can make all the difference.

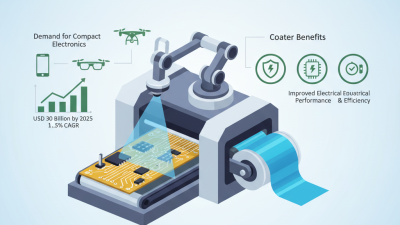

Film coating machines are essential in various industries, including pharmaceuticals, food processing, and electronics. They apply a thin layer of coating to enhance appearance, protect surfaces, and create specific functionalities. Each application has unique requirements, making the selection process crucial.

When choosing a film coating machine, consider the material you will coat. Different materials require different coatings. For example, tablets need a smooth finish while electronics may need protection from moisture. Be clear about your specific needs; this clarity not only saves time but also prevents costly mistakes.

Tip: Research the various types of film coatings. Some are water-based while others are solvent-based. Knowing the pros and cons of each can guide your decision.

Also, think about scalability. Your machine should grow with your production needs. A model that works for small batches may not suffice for larger volumes. It’s worth testing different sizes to find the right fit.

Tip: Don’t overlook maintenance requirements. A machine that seems perfect may need more upkeep than anticipated. This can affect overall productivity.

Ultimately, understanding the applications of film coating machines leads to better choices. Missteps in this area could impact your entire production line. Reflect on what is most important for your operations.

Choosing the right film coating machine involves several critical factors. The machine type is vital. There are various types suited for different applications. Consider a machine based on the materials you work with. Some machines excel with polymers, while others might be better for powders.

Production speed is another key factor. According to industry reports, machines with higher output can improve efficiency by up to 30%. However, speed should not compromise quality. An overly fast machine may not provide a consistent coating, affecting the final product.

Ease of use plays a significant role too. Machines with user-friendly interfaces reduce errors during operation. Training time decreases with intuitive designs. Maintenance is often overlooked. Regular checks prevent downtime. Reports suggest that neglecting maintenance can lead to a 15% increase in operational costs. Weigh these aspects carefully for a successful investment.

When selecting a film coating machine, understanding the various types and their features is crucial. There are generally three main types: pan coaters, fluidized bed coaters, and spray coaters. Each type serves different purposes and offers unique advantages. For instance, pan coaters are known for their versatility and efficiency, particularly in tablet coating applications. Fluidized bed coaters provide uniform coating and are preferred for high-speed processes. According to a recent industry report, the global market for film coating equipment will reach $6.2 billion by 2025.

The features of these machines can vary widely. Some pan coaters come with advanced temperature control systems. This ensures that coatings are applied consistently and at the optimal temperature. However, not every machine will have these features. Some users may encounter performance issues if their equipment lacks such controls. Additionally, fluidized bed coaters, while efficient, can be more challenging to clean. This may lead to downtime and increased maintenance costs.

Choosing the right machine isn't just about features; it's about balancing needs and budget. Data shows that about 40% of manufacturers regret their initial equipment choice. This often stems from underestimating production demands or overlooking maintenance requirements. It's important to assess long-term usage to avoid these pitfalls. Ultimately, the right film coating machine should align with your operational goals and capabilities.

When choosing a film coating machine, assessing your production capacity is crucial. Think about the volume of products you need to coat daily. A machine too small may slow down your operations. Conversely, an oversized machine could lead to wasted resources. Calculate your needs carefully. This includes considering the time each coating process takes. Efficiency is key; every minute counts in production timelines.

Next, consider the types of films you plan to use. Some machines handle specific materials better than others. Pay attention to the thickness and viscosity of your coatings. Explore features that could enhance efficiency, such as automated controls. Automation can help reduce human error and speed up the process. However, it's essential to train staff adequately. A machine's advanced functionality could lead to complications without proper understanding.

Reflect on your long-term goals. Is your production expected to grow? Investing in a machine that accommodates scaling up is wise. But don't overlook maintenance needs. An efficient machine requires regular checks and servicing. An improper maintenance schedule can lead to downtime. Balancing capacity, efficiency, and future growth can be tricky. Yet, these considerations are vital for making a well-informed choice.

Choosing the right film coating machine requires thoughtful consideration of your budget. It's crucial to balance cost and quality. High-end machines offer advanced features, but they can drain your resources. On the other hand, budget options may lack durability. Assess your specific needs before deciding.

Tips: Consider maintenance costs. Some machines require more frequent upkeep, which adds to overall expenses. A slightly higher upfront investment might save you money long-term.

Evaluate your production volume. A machine that accommodates your output goals can boost efficiency. Too little capacity can lead to delays. Analyze production demands carefully; this informs your purchase decision.

Tips: Look for user reviews. These insights can highlight performance issues unseen in specifications. A machine might look good on paper but can disappoint in practice. Trust those with firsthand experience.