In the rapidly evolving landscape of manufacturing, selecting the right Hydrogel Coating Machine is crucial for businesses aiming to enhance product quality and operational efficiency. According to a recent market report by Research and Markets, the global hydrogel market is expected to reach $22.5 billion by 2026, growing at a CAGR of 9.5%. This growth signifies the increasing demand for advanced coating solutions that improve not only functionality but also durability. With various options available, businesses face the challenge of determining which Hydrogel Coating Machine aligns best with their specific operational needs. Factors such as production capacity, coating precision, and technological compatibility must be considered to make an informed decision. This blog will provide essential tips to guide you in selecting the most suitable hydrogel coating machinery, ensuring you stay competitive in this dynamic market.

When considering hydrogel coating machines for your business, it’s essential to understand the key types and technologies available. Hydrogel coatings are widely used in various industries, including medical, automotive, and consumer goods. The most common types of hydrogel coating machines are spray coating, dip coating, and roll-to-roll coating. Spray coating machines provide high precision and uniformity, making them ideal for applications that require intricate designs and fine details. Dip coating, on the other hand, is a cost-effective method for larger substrates, though it may not provide the same level of control over thickness as spray methods. Lastly, roll-to-roll coating machines are perfect for high-volume production, delivering consistent coatings on flexible materials.

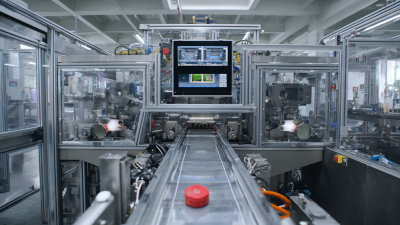

In addition to the machine types, understanding the technologies that drive these coatings is crucial. Many modern hydrogel coating machines utilize advanced features such as automated control systems, real-time monitoring, and eco-friendly materials to enhance efficiency while minimizing waste. Some machines incorporate nanotechnology for better adhesion properties and durability. If your business aims to innovate and enhance product performance, exploring these technological advancements will help in selecting a machine that meets not only your current needs but also supports future growth and sustainability initiatives.

When selecting the right hydrogel coating machine for your business, it’s essential to assess your specific production needs, particularly the capacity and speed requirements. Hydrogel, a water-swollen and cross-linked polymeric network, serves various applications in industries ranging from biomedical to agricultural. Understanding the distinct characteristics and demands of the hydrogel materials you intend to work with can significantly influence your machine choice.

Capacity is a crucial factor in ensuring that your production line can meet market demands. Depending on your business scale, you may require a machine that can handle large volumes of hydrogel coatings efficiently. Additionally, consider the speed at which the machine operates. A faster production speed could enhance your throughput, helping you respond quicker to orders while maintaining quality. Balancing these requirements is key; selecting a machine that meets both the desired capacity and speed will optimize your production process and contribute to the overall success of your hydrogel applications.

When selecting a hydrogel coating machine for your business, evaluating material compatibility is crucial in ensuring optimal performance for your specific application. Hydrogel materials come in various formulations, each offering unique properties such as moisture retention, biocompatibility, and mechanical strength. Understanding these characteristics will help you match the hydrogel with the intended use, whether it's medical devices, cosmetics, or agricultural applications.

Take the time to assess the environmental conditions in which the coated products will be used. For instance, if the application involves exposure to high heat or humidity, choosing a hydrogel that maintains stability under such conditions is essential. Additionally, consider the compatibility of the hydrogel with the substrates involved—some coatings adhere better to certain materials than others. Conducting thorough compatibility tests not only ensures longevity and effectiveness but also minimizes production setbacks and enhances overall product quality.

When evaluating the right hydrogel coating machine for your business, the cost analysis becomes a crucial aspect. The initial investment in high-quality machinery may seem daunting, but understanding the long-term operational efficiency can significantly shift your perspective. Advanced hydrogel coating machines can enhance production rates and reduce material waste, leading to substantial cost savings over time. Investing in energy-efficient technology not only aligns with sustainable practices but also decreases ongoing operational costs, illustrating the long-term value of a higher upfront expense.

When evaluating the right hydrogel coating machine for your business, the cost analysis becomes a crucial aspect. The initial investment in high-quality machinery may seem daunting, but understanding the long-term operational efficiency can significantly shift your perspective. Advanced hydrogel coating machines can enhance production rates and reduce material waste, leading to substantial cost savings over time. Investing in energy-efficient technology not only aligns with sustainable practices but also decreases ongoing operational costs, illustrating the long-term value of a higher upfront expense.

Moreover, integrating AI solutions into the operational framework can further improve efficiency. Many companies are now prioritizing digital investments to tackle skills gaps while boosting innovation. The intersection of advanced machinery and AI can unlock new levels of productivity and precision in hydrogel coating processes. However, it’s important to identify potential challenges and ensure that the technology implemented can scale effectively within your operations. Thus, exploring both the financial and operational dimensions, alongside technological innovations, will ultimately guide you in selecting the best hydrogel coating machine for your business's success.

When investing in hydrogel coating machines, it’s essential to prioritize maintenance and support to ensure the longevity and efficiency of your equipment. Regular maintenance is crucial; it helps prevent potential breakdowns and minimizes downtime that can disrupt production. Establishing a routine check-up schedule not only prolongs the machine’s lifespan but also enhances its performance. Train your staff on basic upkeep procedures and machine diagnostics to address minor issues promptly before they escalate.

Furthermore, choosing a supplier that offers robust customer support can be a game changer. Look for manufacturers that provide comprehensive service agreements, including proactive maintenance and quick response times for repairs. Having access to technical support can greatly reduce your operational headaches, allowing you to focus on your core business. Incorporating these support strategies will not only optimize your hydrogel coating machine's performance but also protect your investment in the long run.