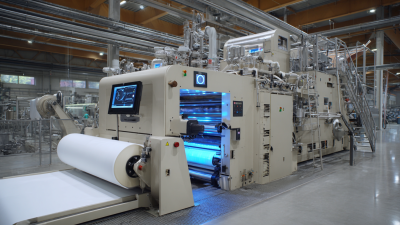

In the fast-paced world of manufacturing, efficiency and production growth are paramount, particularly in the coating industry. A Double-Sided Coating Machine stands out as a pivotal innovation that enhances the coating process for various applications, allowing manufacturers to meet the growing demand for high-quality finished products. According to a recent market analysis by Research and Markets, the global coating machine market is expected to grow significantly, with a projected CAGR of 4.2% from 2021 to 2026. This growth underscores the increasing reliance on advanced technologies, such as double-sided coating systems, which offer more automated and precise coating methods.

In the fast-paced world of manufacturing, efficiency and production growth are paramount, particularly in the coating industry. A Double-Sided Coating Machine stands out as a pivotal innovation that enhances the coating process for various applications, allowing manufacturers to meet the growing demand for high-quality finished products. According to a recent market analysis by Research and Markets, the global coating machine market is expected to grow significantly, with a projected CAGR of 4.2% from 2021 to 2026. This growth underscores the increasing reliance on advanced technologies, such as double-sided coating systems, which offer more automated and precise coating methods.

The role of a Double-Sided Coating Machine extends beyond mere efficiency; it is a game-changer in reducing waste and improving production timelines. By enabling simultaneous coating on both sides of a substrate, these machines significantly cut down manufacturing time, which is crucial in an era where speed to market can make or break a company's competitiveness. Furthermore, manufacturers are increasingly looking to integrate eco-friendly processes, and advanced double-sided machines often come equipped with features that minimize solvent usage and emissions, aligning with global sustainability goals. Understanding the capabilities and advantages of a Double-Sided Coating Machine is essential for any organization aiming to enhance its operational efficiency and adapt to industry demands.

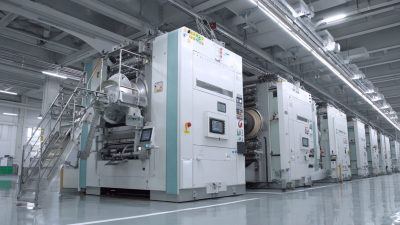

The evolution of double-sided coating machines has played a significant role in enhancing production efficiency across various manufacturing sectors. These machines, capable of simultaneously applying coatings to both sides of a substrate, have witnessed remarkable advancements in technology. As industries increasingly demand higher throughput and quality, double-sided coating machines have adapted by integrating automation, precision control, and improved material handling systems. This evolution not only streamlines the coating process but also reduces waste, contributing to more sustainable manufacturing practices.

In the context of the booming battery manufacturing equipment market, projected to grow substantially by 2030, double-sided coating machines become vital in producing high-performance battery components. The ability to apply uniform coatings efficiently can directly impact the performance and lifespan of batteries, which is essential for electric vehicles and renewable energy storage solutions. Thus, the ongoing improvements in double-sided coating technology not only enhance production capabilities but also align with the broader trends in industries prioritizing innovation and sustainability.

Double-sided coating machines are revolutionizing the coatings industry by enhancing both efficiency and production capabilities. These machines are designed to apply coating materials on both sides of substrates simultaneously, significantly reducing production time and material wastage. According to a market analysis by Technavio, the global coating equipment market is expected to grow by over $8 billion from 2020 to 2024, largely driven by innovations such as double-sided coating technology that enable manufacturers to meet rising demand while optimizing their processes.

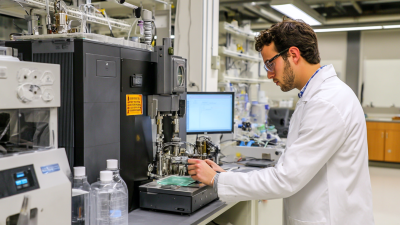

The key features of double-sided coating machines include precision application technology, adjustable coating thickness, and automated operation systems. Advanced technologies, such as roller and curtain coating methods, allow for uniform application and reduced overspray, which is crucial in high-speed production settings. Reports from the Coating Association indicate that manufacturers utilizing double-sided coating machines have experienced a 30% increase in production efficiency, coupled with a notable decrease in material costs. As industries continue to push for sustainability and cost-effectiveness, these machines are positioning themselves as essential tools in modern production lines.

Double-sided coating machines have emerged as a pivotal innovation in the coating industry, playing a significant role in enhancing both efficiency and production growth. These machines enable simultaneous application of coatings on both sides of a substrate, drastically reducing production time and material waste. The dual-sided approach eliminates the need for transferring materials between different stages, streamlining the overall manufacturing process and allowing for higher throughput.

The improvements in coating efficiency achieved with double-sided machines can be attributed to several factors. Firstly, the ability to coat both sides at once not only speeds up the process but also ensures uniform application, resulting in superior quality finishes. Additionally, these machines are often equipped with advanced technology that optimizes the coating application parameters, such as pressure and speed, further enhancing the consistency and adhesion of the coatings. As manufacturers adopt double-sided machines, they can expect significant reductions in operational costs and an increase in productivity, ultimately driving growth in their production capabilities.

Double-sided coating technology has revolutionized various industries by significantly enhancing production efficiency. Companies that have adopted double-sided coating machines report notable improvements in their coating processes. For instance, in the automotive sector, a leading manufacturer integrated this technology into their production line, leading to a 30% increase in output. The machine's capability to apply coatings uniformly on both sides of substrates not only minimizes production time but also reduces material waste, directly impacting the bottom line.

Another compelling example comes from the electronics industry, where a firm specializing in circuit boards utilized double-sided coating technology to streamline its operations. By implementing a double-sided coating machine, they achieved a 40% reduction in cycle time, allowing them to meet rising market demands swiftly. The improved efficiency of applying protective coatings on both sides concurrently enabled the company to significantly enhance the durability of their products while lowering costs associated with labor and materials. These case studies illustrate the tangible benefits of double-sided coating technology, demonstrating its vital role in driving production growth across various sectors.

| Industry Sector | Pre-Coating Efficiency (%) | Production Growth (%) | Implementation Year | Key Benefits |

|---|---|---|---|---|

| Automotive | 88 | 25 | 2021 | Improved adhesion and reduced waste |

| Electronics | 92 | 30 | 2020 | Enhanced durability and efficiency |

| Packaging | 85 | 20 | 2022 | Faster production rates and lower costs |

| Aerospace | 90 | 28 | 2019 | Weight reduction and improved performance |

| Construction | 87 | 22 | 2021 | Durability and eco-friendly solutions |

As industries strive for enhanced efficiency and productivity, double-sided coating machines have emerged as pivotal in various manufacturing sectors. These machines are designed to apply coatings to both sides of materials simultaneously, thereby significantly reducing production time and operational costs. Future trends in the design of these machines are increasingly leaning towards automation and advanced control systems, enabling manufacturers to achieve greater precision and consistency in coating applications. This technological evolution also supports the integration of real-time monitoring systems, allowing for adjustments during the production process, which enhances quality control.

Moreover, innovations in materials used for double-sided coatings are paving the way for new applications. Enhanced substrate compatibility and the development of eco-friendly coating solutions are increasingly demanded by the market. These innovations not only cater to stringent environmental regulations but also meet consumer preferences for sustainable products. Additionally, advancements in the scalability of double-sided coating machines will allow for easier adaptation to various production volumes, making them suitable for both small-scale operations and large manufacturers. This shift underscores the importance of double-sided coating machines as essential tools for future production growth and efficiency in the industrial landscape.