Choosing the right film coating machine is a critical decision for any business involved in the manufacturing or packaging of products. The film coating process not only enhances the aesthetic appeal of products but also provides essential protective layers that can improve durability and shelf life. With a wide array of machines available on the market, it is imperative for businesses to understand the key factors that influence the selection of a film coating machine that aligns with their specific needs.

This guide presents ten essential tips that will help you navigate the complexities of choosing the most suitable film coating machine for your operations. By considering factors such as machine capacity, coating speed, versatility, and ease of operation, you can make informed decisions that will enhance your production efficiency and product quality. Whether you are a small-scale manufacturer or a large industrial operation, understanding these fundamentals will empower you to invest wisely in a film coating machine that meets the unique demands of your business. Make the right choice today for a more productive tomorrow.

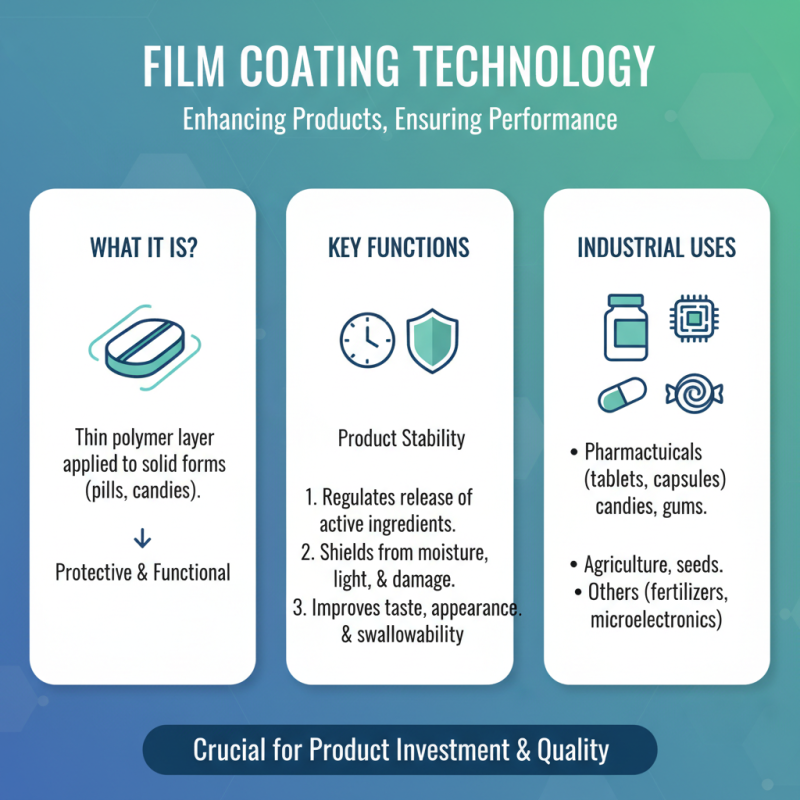

Film coating technology plays a crucial role in various industries, providing a protective layer that enhances the functionality and durability of products. This process involves applying a thin polymer film to solid dosage forms, notably pharmaceuticals and confectionery items, ensuring controlled release of active ingredients and improving product stability. Understanding the fundamentals of film coating is essential for businesses looking to invest in the right machinery that meets their specific needs.

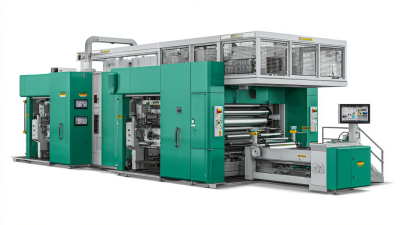

When selecting a film coating machine, consider the scale of production. If your business requires low to medium output, a batch coating machine may be sufficient, while higher production needs might necessitate a continuous system. Additionally, assess the machine's compatibility with different coating materials, as this will affect the versatility and efficiency of your operations.

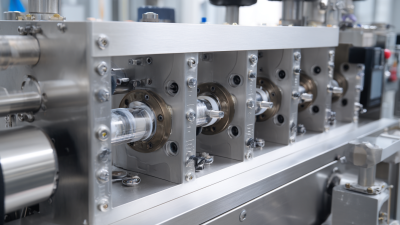

Another vital tip is to evaluate the technological features of the machine, including automation level and ease of use. Machines with advanced control systems can help minimize human error and significantly improve coating uniformity. Moreover, investing in a model with user-friendly interfaces can reduce the learning curve for your staff, ensuring a smoother transition and optimizing productivity from the outset.

When selecting the right film coating machine, it's crucial to start by clearly identifying your business needs and production goals. Understanding the specific requirements of your product can significantly influence your choice. Consider factors such as the size of your operation, the types of materials you will be coating, and the volume of production you expect. These elements will help you understand the machine's capacity and capabilities required to meet your demands efficiently.

Moreover, think about the end-user experience and how the coating will impact the quality and functionality of your product. Aligning your production goals with the performance features of the coating machine is essential to streamline your operations. Additionally, consider future scalability; as your business grows, your chosen equipment should be able to adapt or upgrade to accommodate changes in production volumes or materials. By carefully assessing these factors, you’ll be well-equipped to find a film coating machine that not only meets your immediate needs but also supports your long-term business objectives.

This chart illustrates the important factors businesses should consider when choosing a film coating machine, along with their corresponding weight for decision-making.

When selecting a film coating machine, it is crucial to evaluate the different types available on the market. Generally, film coating machines can be categorized into three main types: conventional coating machines, vacuum coating machines, and automatic coating machines. Each type is designed to meet specific production requirements and product characteristics, which makes understanding their differences essential for any business.

Conventional coating machines utilize a pan or drum to apply the coating material, making them suitable for a wide range of applications. They are typically favored for their versatility and ability to handle batch production efficiently. On the other hand, vacuum coating machines offer enhanced control over the coating environment, reducing the impact of external contaminants and ensuring a uniform application. These machines are particularly beneficial for sensitive products that require a high degree of precision in the coating process.

Automatic coating machines are designed for high-volume production, focusing on efficiency and reduced labor costs. They often incorporate advanced technology such as programmable settings and automation capabilities to streamline operations. Evaluating the specific needs of your business, including production volume, product type, and required coating quality, will help you determine which type of film coating machine is the best fit for your manufacturing process.

When selecting a film coating machine for your business, there are several key features to consider that can significantly impact the efficiency and quality of your operations. Firstly, the capacity and size of the machine are critical. It’s essential to assess the volume of product you plan to coat, as this will determine the machine's throughput capabilities. A suitable machine should be able to handle your production requirements without compromising performance, ensuring you can meet customer demands efficiently.

Another important aspect is the type of coating technology employed by the machine. Different machines may utilize various methods such as spray, dip, or roller coatings, each offering distinct advantages depending on the application. Consider the nature of the products you are working with and the desired finish. Additionally, features such as temperature control, drying mechanisms, and ease of cleaning should be evaluated, as they contribute to both the quality of the coating and the overall maintenance of the equipment.

Ultimately, selecting the right machine involves a careful assessment of how these features align with your specific production needs and operational goals.

When budgeting for a film coating machine, businesses must conduct a thorough cost analysis that encompasses not only the initial purchase price but also long-term operational costs. A report by MarketsandMarkets estimates that the global film coating market will reach $3.57 billion by 2024, indicating significant growth potential. Therefore, investing in the right film coating equipment represents both a crucial cost and an opportunity for competitive advantage in the industry. Companies should anticipate various additional expenses, such as installation fees, maintenance, and potential upgrades, which can accumulate over time.

In addition, it is essential to evaluate the return on investment (ROI) of any film coating equipment. A study published by Mordor Intelligence suggests that efficient film coating processes can reduce material waste by up to 30%, directly impacting the bottom line. Moreover, the operational efficiency brought by newer technologies can lead to higher throughput and better product quality, further justifying the investment. By analyzing these factors closely, businesses can formulate a budget that not only supports the acquisition of the right film coating machine but also ensures sustainable growth and profitability over time.

| Tip No. | Tip Description | Cost Range ($) | Key Features | Considerations |

|---|---|---|---|---|

| 1 | Assess Your Production Needs | 5,000 - 20,000 | Capacity, Speed | Volume of Production |

| 2 | Evaluate Different Types of Machines | 10,000 - 50,000 | Technology, Efficiency | Type of Coating Needed |

| 3 | Consider the Total Cost of Ownership | 15,000 - 70,000 | Maintenance, Parts | Long-term Costs |

| 4 | Look for Energy Efficiency | 3,000 - 25,000 | Energy Rating | Environmental Impact |

| 5 | Check for Warranty and Support | Varies | Customer Support | Service Options |

| 6 | Compare User Experiences and Reviews | N/A | User Feedback | Product Reliability |

| 7 | Explore Financing Options | Varies | Leasing, Loans | Budget Strategy |

| 8 | Assess Safety Features | Varies | Safety Ratings | Compliance Standards |

| 9 | Plan for Future Expansion | 25,000 - 100,000 | Scalability | Growth Potential |

| 10 | Consult with Industry Experts | N/A | Expertise | Informed Decisions |