The demand for advanced electronics continues to surge, driven by innovations across sectors such as

healthcare, automotive, and consumer electronics. According to a report by

MarketsandMarkets, the global flexible printed circuit board market is anticipated to reach

$30 billion by 2026, growing at a CAGR of 8.5% from 2021.

Central to this progress is the Flexible Circuit Board Coater, which enables the creation of versatile and efficient circuit designs that can be seamlessly

integrated into compact and intricate electronic devices. This blog will explore

real-world applications of the best Flexible Circuit Board Coater, highlighting its role in enhancing product functionality

and durability while addressing the challenges faced in the manufacturing process. By examining case studies across various industries,

we aim to showcase how this innovative technology not only revolutionizes electronic design but also streamlines production, ultimately

fostering a more sustainable and responsive technological landscape.

Central to this progress is the Flexible Circuit Board Coater, which enables the creation of versatile and efficient circuit designs that can be seamlessly

integrated into compact and intricate electronic devices. This blog will explore

real-world applications of the best Flexible Circuit Board Coater, highlighting its role in enhancing product functionality

and durability while addressing the challenges faced in the manufacturing process. By examining case studies across various industries,

we aim to showcase how this innovative technology not only revolutionizes electronic design but also streamlines production, ultimately

fostering a more sustainable and responsive technological landscape.

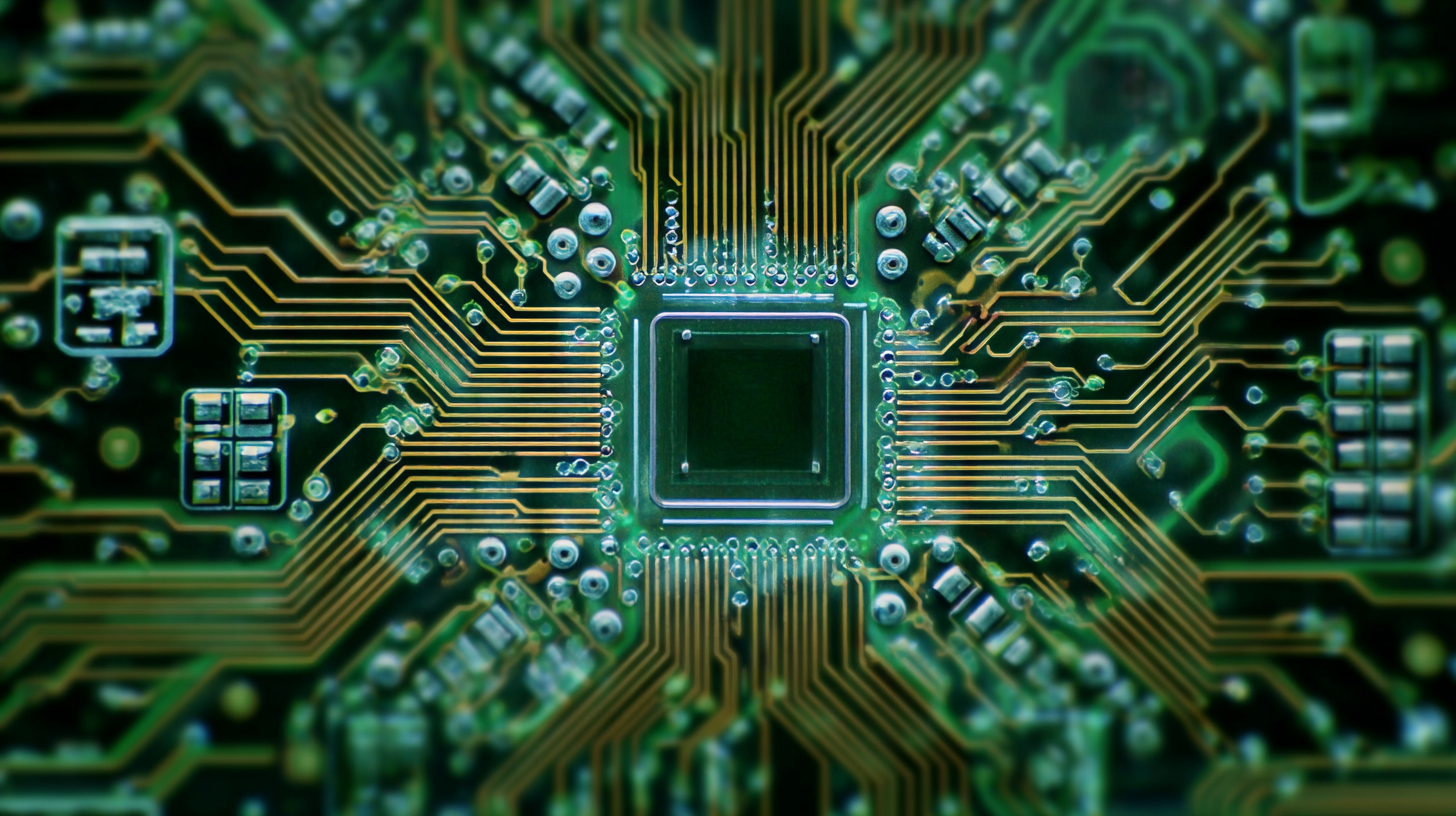

Flexible circuit boards have significantly revolutionized the landscape of modern electronics, paving the way for innovation across various industries. Initially, traditional rigid circuit boards posed limitations in terms of size and design flexibility, making it challenging to create compact and lightweight devices. However, the evolution of flexible circuits has enabled manufacturers to design products that conform to unique shapes and adapt to dynamic environments. This transformation has been particularly impactful in sectors such as consumer electronics, medical devices, and automotive applications, where size constraints and weight are critical.

Moreover, advancements in flexible circuit board technology have facilitated the integration of more complex functionalities. The ability to print circuits directly onto flexible substrates allows for the seamless incorporation of sensors and other components, making devices smarter and more efficient. This evolution not only enhances the performance of electronic products but also fosters the development of wearable technologies and IoT devices, which require both flexibility and robustness. However, manufacturers still face challenges in terms of material durability, production costs, and fabrication techniques, which will need to be addressed as demand for flexible circuits continues to grow.

| Application Area | Material Type | Key Benefits | Challenges |

|---|---|---|---|

| Wearable Devices | Polyimide (PI) | Lightweight, Flexible, Durable | High Manufacturing Costs |

| Consumer Electronics | Copper-Flex Laminate | Improved Space Efficiency | Thermal Management Issues |

| Automotive | FR-4 | Reliable Performance in Harsh Conditions | Regulatory Compliance |

| Aerospace | Ceramic-Based Materials | High Reliability and Low Weight | Cost and Complexity |

| Medical Devices | Silicone-Based Circuits | Bio-Compatibility, Flexibility | Strict Regulatory Standards |

The evolution of electronic manufacturing has been significantly influenced by advanced circuit board coating technologies, which enhance the functionality and reliability of flexible circuit boards. The integration of features such as high durability, water resistance, and thermal stability has made these coatings indispensable in various applications, particularly in automotive and consumer electronics. With the rising demand for miniaturized devices, these advanced coatings provide the necessary protection while allowing for increased design flexibility.

One noteworthy trend in the market is the growing adoption of roll-to-roll (R2R) coating technologies, known for their high throughput and eco-friendliness. These processes are integral to the efficient production of flexible circuit boards, capitalizing on modern material synthesis techniques. Additionally, innovations like Direct Laser Writing (DLW) not only enhance material conversion but also streamline the processing of electronic devices, ensuring that manufacturers can meet the escalating demands of the industry while maintaining cost-effectiveness and high-resolution outputs. As the landscape of electronics continues to transform, these key features and benefits of advanced coating technologies will play a pivotal role in shaping the future of flexible circuit boards.

The growing demand for flexible circuits across various industries is reshaping the electronics landscape. As technology continues to evolve, industries such as automotive, aerospace, and consumer electronics are increasingly adopting flexible circuit boards. This shift is driven by the need for lightweight, space-saving solutions that can accommodate the complex designs of modern electronic devices. Moreover, advancements in flexible circuit production technology are enabling manufacturers to meet the rising demands of high-performance, reliable products.

Market projections highlight the significance of this trend. The global semiconductor etching equipment market is anticipated to expand from $14.51 billion in 2024 to $28.26 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 8.7%. Concurrently, the industrial printers market is poised for substantial growth, driven by the push towards industrial automation and digitalization—expected to surpass $91.7 billion by 2024. Furthermore, the versatile and reliable YY control cable market is also on track for an 8.7% CAGR growth, indicating a widespread adaptation across different sectors. As these markets evolve, the integration of flexible circuits will likely play a vital role in enhancing performance and efficiency in modern applications.

The manufacturing of flexible circuit boards presents several challenges that can hinder production efficiency and product quality. One major issue is the delicate nature of the materials involved. Unlike traditional rigid circuit boards, flexible circuits require precise handling and processing to avoid damaging the substrates. This sensitivity can lead to increased waste and elevated costs during the manufacturing process.

Moreover, achieving uniform coating and reliable adhesion in a variety of temperatures and environments adds another layer of complexity.

Moreover, achieving uniform coating and reliable adhesion in a variety of temperatures and environments adds another layer of complexity.

To address these challenges, manufacturers are turning to advanced flexible circuit board coaters equipped with cutting-edge technology. Automated systems with precise control over coating thickness and application speed can significantly reduce human error and material waste. Furthermore, investing in high-quality materials that enhance flexibility and durability can help mitigate performance issues, ensuring that the final product meets stringent industry standards.

By embracing innovation and improving manufacturing techniques, the production of flexible circuit boards can become more efficient and economical, paving the way for broader applications across various industries.

The integration of flexible circuit boards (FCBs) in various industries has surged, driven by advancements in coating technologies. A recent report by MarketsandMarkets projects that the flexible printed circuit boards market is expected to reach $30.11 billion by 2025, exhibiting a CAGR of 10.2% from 2020. This growth is further fueled by successful implementations of flexible circuit board coaters that have proven their efficiency in real-world applications, particularly in consumer electronics, medical devices, and automotive sectors.

One standout case is the collaboration between a leading automotive manufacturer and a flexible circuit board coater company, which resulted in a significant enhancement in the performance of in-vehicle displays. By utilizing advanced coating technology, they reduced the overall weight of circuit assemblies by 15%, leading to improved fuel efficiency. In the medical field, a hospital implemented flexible circuit boards in wearable health monitoring devices, where the option for conformal coatings has allowed for durable and reliable functionality in diverse environments. These examples illustrate not only the adaptability of flexible circuits but also the substantial benefits they present in terms of performance enhancements and cost efficiency, positioning them as a vital component of modern electronic designs.