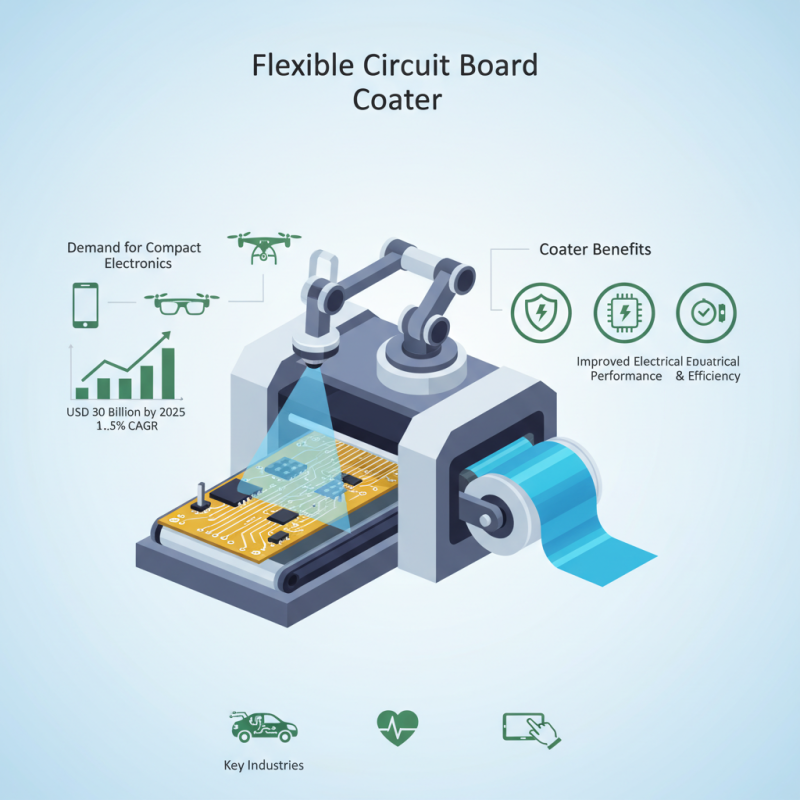

The rise in demand for lightweight and compact electronic devices has significantly influenced the growth of the flexible circuit board market. According to a report by MarketsandMarkets, the global flexible printed circuit board market is projected to reach USD 30 billion by 2025, growing at a CAGR of 10.5% from 2020 to 2025. As industries increasingly adopt miniaturization and innovative designs, the need for efficient manufacturing processes for flexible circuit boards has become paramount. A vital component in this manufacturing landscape is the Flexible Circuit Board Coater, which plays a crucial role in enhancing production efficiency and quality.

Flexible Circuit Board Coaters are specialized machines designed for applying protective and functional coatings to flexible circuit boards. These coatings not only safeguard the circuitry from environmental factors but also improve electrical performance. Given that the demand for reliable and durable electronic components continues to surge, the significance of advanced coating technologies cannot be overstated. Reports indicate that improvements in coating processes can lead to better adhesion, reduced manufacturing time, and increased product longevity, translating into significant cost savings and enhanced product reliability. As industries such as automotive, consumer electronics, and healthcare increasingly incorporate flexible circuits, understanding the workings and benefits of a Flexible Circuit Board Coater is essential for organizations aiming to stay competitive in a rapidly evolving market.

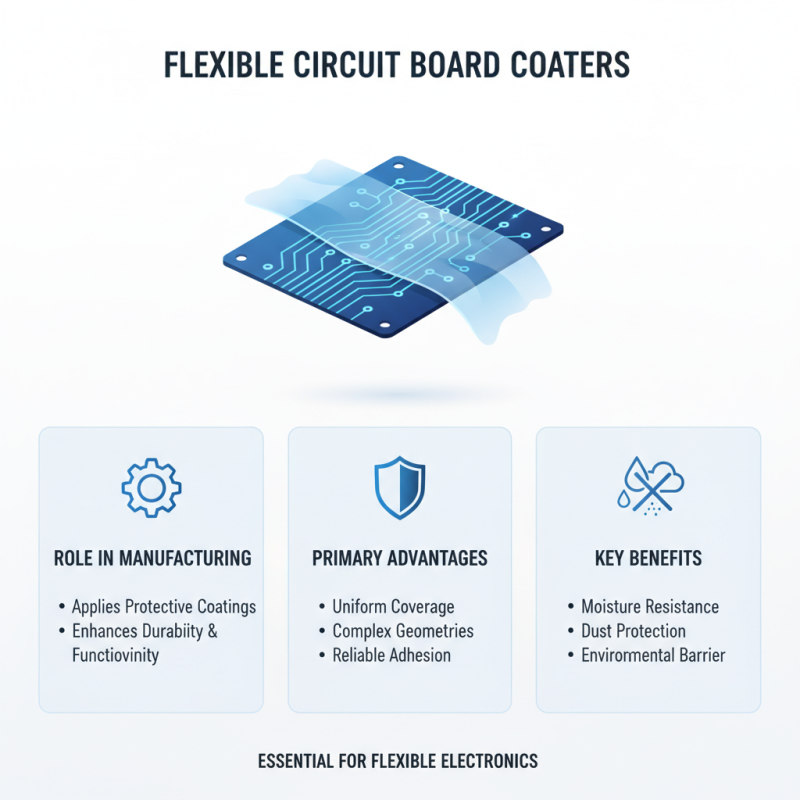

A Flexible Circuit Board Coater is a specialized piece of equipment designed for applying coating materials to flexible circuit boards, providing essential protection and enhancing their performance. These coaters utilize advanced technology to ensure uniform application of coatings, which may include adhesives, solder masks, and conformal coatings. By safeguarding the circuits from environmental factors like moisture, dust, and chemicals, a coater significantly extends the lifespan of flexible electronic components.

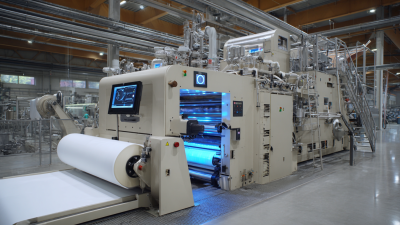

The operation of a Flexible Circuit Board Coater involves several key processes. First, the circuit boards are prepared and positioned on the coating platform. The coater then uses various methods, such as spray, dip, or curtain coating, to evenly distribute the coating material across the surfaces of the boards. Once applied, the coating usually undergoes a curing process, either through heat or UV light, to achieve optimal adhesion and protective qualities. This precise and controlled application ensures that even intricate designs on flexible circuit boards receive the protection they need while maintaining their functionality and reliability.

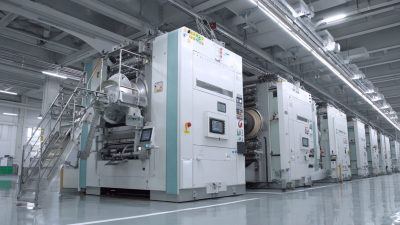

Flexible circuit board coaters are specialized machines designed to apply coatings to flexible printed circuits to enhance durability and functionality. The key components of these coaters play a vital role in determining their efficiency and effectiveness. Understanding these components helps in optimizing the coating process for flexible circuits, which are increasingly utilized across a variety of industries including electronics, automotive, and medical devices.

One of the most critical components of a flexible circuit board coater is the dispensing system. This system ensures precise application of coating materials, which can include conformal coatings, encapsulants, or adhesives. Industry reports indicate that precision in coating applications can significantly reduce material waste and enhance the end product’s reliability. Additionally, the curing system is another key element, providing the necessary environment to ensure that coatings fully cure and adhere correctly. Innovations in UV and thermal curing technologies have shown improvements in efficiency—minimizing cycle times while maintaining high-quality finishes.

Another essential component is the control system, which manages the coating parameters such as speed, pressure, and thickness. Advanced control technologies allow for real-time monitoring and adjustments, accommodating different types of flexible substrates. According to market research reports, the demand for automated coating systems is expected to grow by over 10% annually, driven by the need for more robust and reliable electronic devices. As flexible circuits become more prevalent, the enhancements in coater design and technology will be crucial to meeting stringent performance standards.

| Component | Description | Function |

|---|---|---|

| Coating Head | The part that applies the coating material onto the flexible circuit. | Ensures even and accurate distribution of the coating material. |

| Curing System | Utilizes UV light or heat to cure the applied coating. | Hardens the coating for durability and protection. |

| Substrate Holder | Holds the flexible circuit board in place during coating. | Prevents movement and ensures precision during the coating process. |

| Nozzle | A component that controls the flow of coating material. | Regulates the amount and thickness of the coating applied. |

| Control System | Interface for operating the coater. | Allows for adjustments in parameters like speed and pressure. |

| Safety Features | Include sensors and emergency shut-off systems. | Protects operators and equipment from hazards. |

The coating process for flexible circuit boards is a meticulous operation designed to enhance the board's performance and lifespan. Initially, the circuit board is thoroughly cleaned to remove any contaminants or residues that could interfere with adhesion. This cleaning step ensures that the surface is ready to receive the coating material. Following this, a primer may be applied to facilitate bonding between the board and the coating, often enhancing its durability and functionality.

Once prepared, the flexible circuit board undergoes the actual coating application. This can be achieved through various methods, including dip coating, spray coating, or screen printing. Each technique has its advantages and is chosen based on the specific requirements of the circuit board design. After the coating is applied, the board typically goes through a curing process, where heat or UV light solidifies the coating material, forming a robust protective layer. This step not only secures the coating's adhesion but also optimizes its electrical insulating properties, making the flexible circuit board suitable for applications across diverse industries.

Flexible circuit board coaters play a crucial role in the manufacturing of flexible electronics by applying protective coatings that enhance durability and functionality. One of the primary advantages of using these specialized coaters is their ability to provide uniform coverage over complex geometries, which is essential for maintaining the integrity of intricate circuits. This uniformity ensures that the coatings adhere properly and create a reliable barrier against moisture, dust, and other environmental contaminants.

Another significant benefit of flexible circuit board coaters is the efficiency they bring to production processes. These systems are designed for rapid application, reducing both time and labor costs associated with manual coating methods. Furthermore, advanced coater technology allows for precise control of thickness and material properties, which can optimize the performance of the circuits while minimizing waste.

Tips: When considering flexible circuit board coaters, it's important to evaluate the compatibility of the coating materials with your circuit's substrates. This ensures optimal adhesion and performance. Additionally, regular maintenance of the coating equipment can prevent common issues such as clogging and inconsistent application, which can affect product quality over time.

Flexible circuit board coaters are widely utilized across various industries due to their efficiency in applying protective coatings. These coaters play a crucial role in the electronics sector by enhancing the durability and performance of flexible printed circuits (FPCs). Industries such as automotive, medical devices, and consumer electronics benefit significantly from these advanced coating technologies. In automotive applications, flexible circuit board coaters protect vital components from harsh environments, ensuring the reliability of safety systems and infotainment units.

In the medical sector, flexible circuit board coaters provide essential insulation and protection for devices that require precision and durability, such as wearable health monitors and diagnostic equipment. The flexibility offered by these coatings is crucial for devices that conform to body shapes or fit within compact spaces. Meanwhile, consumer electronics manufacturers utilize flexible circuit board coaters to improve the performance of smartphones, tablets, and wearable gadgets, helping to safeguard against moisture and other environmental factors that could compromise functionality. As industries continue to innovate, the demand for flexible circuit board coaters will likely expand, allowing for more sophisticated designs and enhanced product reliability.