In the world of leather manufacturing, the Leather Coating Machine plays a pivotal role in enhancing the quality and durability of leather products. This machine is designed to apply protective coatings and finishes that not only improve the aesthetic appeal of the leather but also provide essential resistance to wear and environmental factors. Understanding the functionality of a Leather Coating Machine is crucial for manufacturers seeking to optimize their production processes and ensure their products meet the highest industry standards. From the types of coatings applied to the intricacies of the machine's operation, this article will explore essential tips and insights to help you fully appreciate the capabilities of this innovative equipment. By grasping the key features and benefits of a Leather Coating Machine, you can significantly improve your leather goods' overall performance and marketability.

A leather coating machine serves a vital role in the leather production process, primarily aimed at enhancing the durability and appearance of leather products. The core purpose of this machine is to apply a protective layer over leather surfaces, which not only provides resistance to wear and tear but also improves aesthetic qualities such as color depth and glossiness. According to a report by Smithers Pira, the global leather market is projected to grow to $413 billion by 2025, emphasizing the increasing demand for high-quality leather goods. This growth has pushed manufacturers to invest in advanced coating technologies to meet consumer expectations and industry standards.

Furthermore, leather coating machines enhance the functional properties of leather, such as resistance to water, UV light, and stains. Research conducted by Leather Naturally indicates that over 70% of leather manufacturers are integrating innovative coating solutions to improve product performance. By employing these machines, manufacturers ensure that their leather products can withstand environmental challenges, thereby prolonging their lifespan. The integration of eco-friendly coatings is also on the rise, with a significant number of companies adopting sustainable practices to cater to the environmentally conscious consumer.

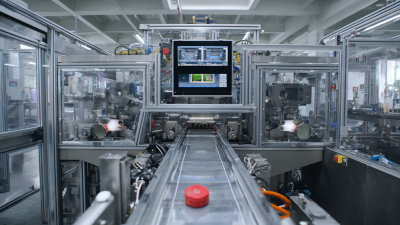

A leather coating machine plays a crucial role in the production of high-quality leather products. The functionality of these machines is deeply rooted in their essential components, which work together to ensure the application of coatings is efficient and uniform. One key component is the coating head, which is responsible for applying the coating material to the leather substrate. This head can be designed to accommodate various application methods, such as spray or roll coating, allowing for flexibility depending on the desired finish.

Another fundamental element is the drying and curing system. After the initial coating is applied, the leather must be dried and cured to set the finish properly. This system typically utilizes controlled temperature and airflow to achieve optimal results, preventing issues like uneven drying or damage to the leather. Additionally, the machine may include sensors and automation systems that monitor and adjust the coating process in real-time, ensuring consistent quality across batches. Together, these components form an integrated system that enhances the functionality of leather coating machines, ultimately contributing to the production of durable and aesthetically pleasing leather goods.

Leather coating machines play a crucial role in the leather manufacturing process, primarily focusing on enhancing the surface finish and durability of leather products. The operation of these machines typically involves a systematic flow that starts with the preparation of the leather substrate, which could be raw or semi-finished leather. The surface is first cleaned and treated to ensure optimal adhesion of the coating materials.

Once prepared, the leather is passed through the coating machine where it undergoes a series of processes. Initially, a base coating is applied evenly across the surface using rollers or spray systems. This layer not only enhances the leather's appearance but also provides a protective barrier against stains and moisture. Following the base layer, additional coatings such as color, texture, and finishing coats are applied as per the desired specifications. After coating, the leather is subjected to drying and curing phases to ensure that all layers bond effectively and comply with quality standards. This meticulous process enhances the overall aesthetics and longevity of the final leather product.

The leather industry has seen significant advancements with the introduction of leather coating machines, which enhance the efficiency and quality of production. According to a report by Grand View Research, the global leather goods market size was valued at USD 400.5 billion in 2021 and is projected to grow at a CAGR of 5.4% from 2022 to 2030. This surge in demand places an emphasis on the need for efficient manufacturing processes, where leather coating machines play a critical role.

One of the main benefits of using a leather coating machine is the consistent application of coatings that ensure uniformity across batches. This technology not only improves the aesthetic appeal of leather products but also enhances durability and resistance to wear and tear. Studies show that correctly applied coatings can increase the lifespan of leather by up to 20%, reducing the need for frequent replacements and thereby supporting sustainability efforts in the industry. In fact, a report by McKinsey & Company highlights that implementing advanced machinery can lead to a 30% increase in production efficiency in the leather sector, thereby driving down costs and elevating product quality.

| Feature | Description | Benefits |

|---|---|---|

| Coating Thickness Control | Allows precise adjustments to the thickness of the coating applied to leather. | Ensures consistent quality and reduces material waste. |

| Adjustable Speed Settings | Enables the operator to adjust the speed of the coating process. | Improves efficiency and allows for adaptation to different leather types. |

| Eco-Friendly Options | Compatible with eco-friendly coating materials. | Enhances sustainability in leather production. |

| User-Friendly Interface | Designed for easy operation with clear controls. | Reduces training time and minimizes operator errors. |

| Versatile Application | Can be used for various types of leathers and substrates. | Increases productivity by accommodating multiple products. |

| Enhanced Durability | Provides a protective layer enhancing the wear resistance of leather. | Extends the lifespan of leather products, reducing replacement costs. |

Leather coating machines play a crucial role in various industries by enhancing the functionality and aesthetic appeal of leather products. In the fashion and accessories sector, these machines are essential for applying protective coatings that improve durability while maintaining the leather's natural look and feel. Reports indicate that the global leather goods market is expected to reach a value of over $400 billion by 2025, driven in part by innovations in leather processing technologies, including advanced coating techniques.

In addition to fashion, leather coating machines find significant utility in the automotive industry. Coatings applied to leather interiors not only enhance their appearance but also provide resistance against wear, stains, and fading due to UV exposure. A recent survey revealed that improving leather quality in vehicles could raise customer satisfaction ratings by more than 20%. Moreover, the integration of sustainable practices, such as the use of eco-friendly coatings, aligns with the industry's shift toward greener alternatives, particularly in response to the rising popularity of mycelium materials as leather substitutes and advancements in environmental stewardship.