In the rapidly evolving landscape of manufacturing technology, choosing the right equipment can significantly impact efficiency and product quality. Among the numerous innovations, the Hydrogel Coating Machine stands out as a pivotal tool for businesses looking to enhance their production processes.

This guide aims to equip manufacturers with the essential knowledge needed to select the most suitable Hydrogel Coating Machine tailored to their specific operational demands. From understanding the fundamental features and benefits of these machines to evaluating various models in terms of performance and cost-effectiveness, we will explore critical factors that should influence your decision-making process.

Whether you're a seasoned professional in the industry or a new entrant seeking to invest in advanced coating solutions, this ultimate guide will serve as a comprehensive resource to navigate the complexities of selecting the ideal Hydrogel Coating Machine for your manufacturing needs.

This guide aims to equip manufacturers with the essential knowledge needed to select the most suitable Hydrogel Coating Machine tailored to their specific operational demands. From understanding the fundamental features and benefits of these machines to evaluating various models in terms of performance and cost-effectiveness, we will explore critical factors that should influence your decision-making process.

Whether you're a seasoned professional in the industry or a new entrant seeking to invest in advanced coating solutions, this ultimate guide will serve as a comprehensive resource to navigate the complexities of selecting the ideal Hydrogel Coating Machine for your manufacturing needs.

Hydrogel coatings have emerged as a significant innovation in the manufacturing sector, offering protective and functional capabilities that enhance product durability and performance. These coatings are meticulously designed to harness the benefits of graphene—an extraordinary material known for its mechanical strength, thermal conductivity, and corrosion resistance. The integration of graphene into hydrogel coatings not only improves their properties but also extends their applications across various industries, including electronics, automotive, and healthcare.

The global market for water-based coatings, which includes hydrogels, is poised for substantial growth. By 2025, the market is projected to reach approximately $5.746 billion, with a compound annual growth rate (CAGR) of 5.3% expected through to 2033. This growth reflects an increasing demand for eco-friendly and sustainable solutions in manufacturing processes, driving innovation in the development and commercialization of protective and functional coatings. As manufacturers seek to comply with environmental standards and improve product longevity, investing in high-quality hydrogel coating machines becomes essential to stay competitive in this evolving landscape.

When selecting a hydrogel coating machine for your manufacturing needs, several key factors must be considered to ensure optimal performance and efficiency. First and foremost, it's essential to evaluate the machine's coating precision. High precision is vital for consistent product quality, especially in industries where accuracy is critical. Look for machines that offer adjustable settings to fine-tune the coating thickness and uniformity as per your product specifications.

Tip: Always check for user reviews or case studies that highlight the machine's performance in real-world applications. This can provide valuable insights into its reliability and functionality.

Another crucial factor is the machine's capacity and speed. Depending on your production volume, you will need a machine that can handle your specific output requirements without compromising on quality. Additionally, consider the machine's compatibility with different types of hydrogel materials, as this will expand your product range and flexibility.

Tip: Ask manufacturers about their after-sale support and maintenance services. A good service guarantee can save you time and money in the long run by ensuring your machine runs smoothly and efficiently.

When selecting a hydrogel coating machine, understanding production capacity and efficiency metrics is crucial for aligning the equipment with your manufacturing needs. The production capacity of a hydrogel coating machine typically refers to the volume of product that can be processed within a specific timeframe. Evaluating this metric is essential for ensuring that the machine can handle your projected output without causing delays or bottlenecks in your production line. Manufacturers should consider both the machine's maximum output per hour and the nature of the hydrogel being applied, as varying viscosities and application techniques can impact throughput.

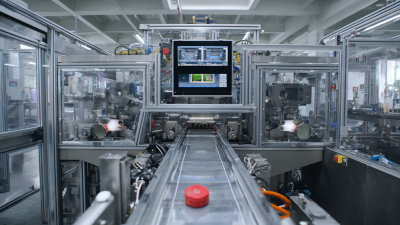

Efficiency metrics, on the other hand, provide insight into how well the machine operates relative to its output. This includes assessing waste levels, energy consumption, and the time taken for changeovers between production runs. Machines that offer quick setup times and minimal waste during the coating process can significantly enhance overall productivity. Additionally, embracing automation features can optimize efficiency further by reducing manual intervention and streamlining operational workflows. By thoroughly analyzing production capacity alongside efficiency metrics, manufacturers can make informed decisions when investing in hydrogel coating machinery tailored to their operational goals.

When selecting a hydrogel coating machine, it’s essential to compare the leading options in the market to determine which best meets your manufacturing requirements. A recent report from the Global Hydrogel Market Forecast indicates that the demand for hydrogel products is expected to grow at a CAGR of 6.5% through 2028, driven by advancements in biomedical applications and consumer products. Key features to consider in a hydrogel coating machine include precision, speed, and the ability to handle various substrate materials.

Among the top contenders, the XYZ Hydrogel Coater stands out with its advanced automatic feed system that enhances productivity by reducing downtime. This machine offers customizable coating thicknesses ranging from 5 to 50 micrometers, catering to diverse applications. Additionally, the ABC Series boasts an innovative temperature control mechanism, ensuring optimal viscosity for a consistent application. According to a comprehensive analysis by Industry Insights, machines like the XYZ and ABC series are projected to dominate the market, thanks to their cutting-edge technology and reliability in producing high-quality hydrogel coatings.

Investing in hydrogel coating technology can significantly enhance manufacturing efficiency and product quality. A cost-benefit analysis reveals that while the initial investment may seem substantial, the long-term advantages often outweigh the costs. Businesses utilizing hydrogel coatings can expect reduced wastage, improved adhesion, and enhanced product durability, all of which contribute to greater customer satisfaction and potentially lower production costs.

When considering the purchase of a hydrogel coating machine, it's essential to evaluate your specific manufacturing needs. Tip 1: Assess the scalability of the machine to ensure it can accommodate future production increases. This forward-thinking approach ensures that your investment remains relevant as your business grows.

Additionally, look into the machine's ease of use and maintenance requirements. Tip 2: Choose equipment that offers user-friendly features and accessible support services. This will not only streamline your operations but also minimize downtime and training costs, ultimately providing better returns on your investment. By carefully evaluating these aspects, businesses can make informed decisions that lead to sustainable growth and enhanced productivity in the long run.