In today's fast-paced manufacturing environment, sourcing top quality suppliers for Aluminum Foil Coating Machines is crucial for businesses aiming to enhance their production processes and maintain competitive advantage. With the growing demand for high-performance aluminum foil products in various industries, finding the right machine can significantly impact product quality and operational efficiency. However, identifying reputable suppliers amidst a sea of options can be daunting.

This definitive guide serves as a comprehensive checklist to assist businesses in navigating the supplier landscape for Aluminum Foil Coating Machines, ensuring they select partners who deliver reliability, innovation, and exceptional support. By following this guide, companies can streamline their sourcing process, making informed decisions that will contribute to long-term success and sustainability.

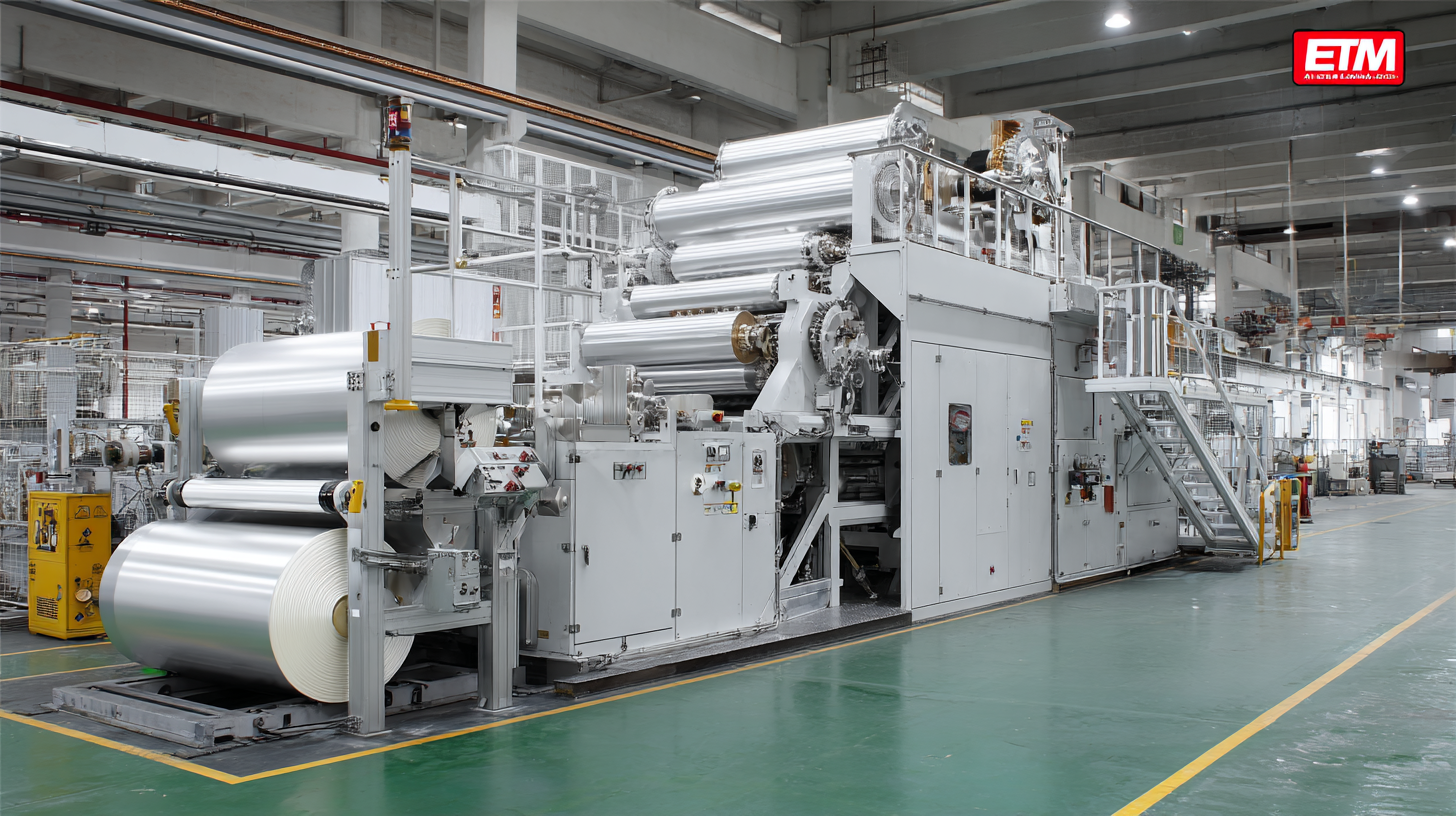

When sourcing high-quality aluminum foil coating machines, it's crucial to identify their key features to ensure optimal performance and longevity. A well-designed aluminum foil coating machine should exhibit superior coating precision, adjustable application rates, and the ability to handle various foil thicknesses. Industry reports indicate that machines with automated control systems can increase production efficiency by up to 30%, reducing labor costs and minimizing human error.

Tip: Always look for suppliers that offer machines with customizable features to suit specific production needs. For instance, consider machines equipped with advanced heating systems and non-stick coatings that facilitate easier maintenance and enhance product quality.

Another essential feature to consider is energy efficiency. Recent studies show that selecting machines with lower energy consumption can result in a 15-20% reduction in operational costs over time. Moreover, the durability of components used in construction is vital for minimizing downtime and repair costs.

Tip: When evaluating suppliers, request machine performance data and customer testimonials to gauge reliability and service support. This hands-on insight can be invaluable in making informed purchasing decisions.

When it comes to aluminum foil coating processes, understanding the various methods available is essential for making informed decisions. The most common types include wet coating, dry coating, and vacuum coating.

Wet coating involves applying a liquid coating material onto the foil surface, which is then dried to create a smooth, uniform finish. This method is widely used for its versatility and ability to produce intricate designs, making it ideal for packaging applications that require both aesthetics and functionality.

Dry coating, on the other hand, utilizes powdered coatings that are transferred to the foil via electrostatic spraying or mechanical means. This process offers several advantages, including environmental benefits due to the reduction of volatile organic compounds (VOCs) and the ability to create thicker coatings.

Additionally, vacuum coating is a high-precision method where aluminum foil is placed in a vacuum chamber, allowing for the deposition of thin films of material. This technique is often employed for applications that demand superior barrier properties, such as food packaging and electronics.

Each coating process has its unique set of benefits and limitations, which makes it crucial to select the appropriate method based on your specific application needs. By understanding these processes, you can better evaluate potential suppliers and their capabilities in delivering high-quality aluminum foil coating machines tailored to your requirements.

When looking to source top-quality aluminum foil coating machine suppliers, evaluating them effectively is crucial to your production success. Start by focusing on the supplier’s experience in the industry. A supplier with a solid track record and extensive expertise can often provide better insights into the machines needed for your specific requirements.

Another essential tip is to assess the technology and machinery they use. The suppliers should offer state-of-the-art equipment that meets the latest industry standards. This guarantees not only the quality of the aluminum foil but also enhances efficiency in the manufacturing process. Verify the specifications and consider requesting samples to evaluate the machine performance before making a commitment.

Lastly, don't overlook customer support and service. A reliable supplier should offer comprehensive support, including installation and maintenance service, to ensure that your machine operates smoothly. Good after-sales service can significantly reduce downtime and improve your overall production efficiency.

When sourcing aluminum foil coating machines, one of the critical decisions buyers face is whether to opt for local or international suppliers. Local suppliers often provide the advantage of easier communication and faster response times, which can be crucial for technical support and maintenance. Additionally, these suppliers may possess a better understanding of regional market needs and regulatory requirements, thus ensuring that the machines comply with local standards. The ability to visit a local supplier's facility can also enhance trust and allow buyers to inspect the machinery firsthand, which is invaluable in the decision-making process.

On the other hand, international suppliers may offer a wider range of technological advancements and competitive pricing due to lower manufacturing costs. They often have established reputations that stem from years of experience in the global market, which can translate into higher quality products and innovative features. However, potential challenges include longer lead times for shipping and potential communication barriers that can arise due to time zone differences and cultural nuances. In weighing local versus international suppliers, businesses must carefully consider their specific operational needs, the importance of support and service, and their budget constraints to make an informed choice.

When sourcing aluminum foil coating equipment, avoiding common pitfalls can save time and money.

One significant mistake is neglecting to verify supplier credentials. According to a report by MarketsandMarkets, the global aluminum foil market is expected to reach

USD 56.06 billion by 2025, indicating a surge in demand for reliable suppliers. Always request certifications and inspect reviews before making commitments.

Another frequent error is focusing solely on price without considering quality. A cheap machine might lead to higher operational costs in the long run due to frequent repairs or inadequate performance.

The International Aluminium Institute suggests that investing in high-quality machinery can enhance productivity and reduce wastage, thus improving overall efficiency.

Tip: When assessing a supplier, inquire about their after-sales support and warranty terms. Reliable suppliers often provide robust customer service and maintenance packages.

Tip: Always conduct a factory visit or request production capability reports to ensure the supplier meets your quality standards and can handle your specific production needs.

By avoiding these mistakes, you can ensure a smoother sourcing process and better return on investment.