In today's fast-paced global market, the demand for high-quality optical film coating machines has surged significantly, driven by advancements in technology and increased applications across various industries, including electronics, automotive, and renewable energy. According to a recent report by MarketsandMarkets, the optical coating market is projected to reach $13.2 billion by 2025, growing at a CAGR of 5.3% from 2020. This rapid growth underscores the importance of navigating the complexities of import and export certifications that manufacturers of optical film coating machines must adhere to in order to access international markets. Understanding these certifications not only ensures compliance with regulatory requirements but also helps businesses maintain competitive advantages and enhance product quality.

In this comprehensive tutorial, we will explore the crucial aspects of securing import and export certifications to streamline the procurement and distribution processes of optical film coating machines.

The optical film coating industry plays a crucial role in various sectors, including consumer electronics, automotive, and healthcare. As global demand for advanced optical films increases, understanding the importance of import-export certifications becomes vital for manufacturers and distributors. According to a report by MarketsandMarkets, the optical coatings market is projected to reach USD 16.75 billion by 2025, growing at a CAGR of 7.6%. Navigating the regulatory landscape of import and export certifications ensures compliance with international standards, enabling businesses to enhance their credibility and expand their market reach.

Import-export certifications not only serve as a gateway to international markets but also guarantee product quality and safety. For instance, certifications like ISO 9001 and CE mark signify adherence to quality management systems and European safety standards, respectively. The International Trade Centre (ITC) notes that products with recognized certifications enjoy a competitive advantage, improving customer trust and increasing sales potential. As manufacturers streamline their certification processes, it can significantly reduce time-to-market and minimize the risks associated with global trade. In a rapidly evolving industry, prioritizing import-export certifications is essential for businesses aiming to capitalize on emerging opportunities.

When it comes to investing in optical film coating machines, understanding the key certifications is crucial for compliance and quality assurance. These certifications not only validate the machine's operational efficiency and safety standards but also ensure that the equipment meets the specific requirements of various industries. For buyers and manufacturers alike, familiarity with certifications such as ISO standards, CE markings, and industry-specific validations can provide a competitive edge in a growing market, projected to reach significant value by 2030.

When it comes to investing in optical film coating machines, understanding the key certifications is crucial for compliance and quality assurance. These certifications not only validate the machine's operational efficiency and safety standards but also ensure that the equipment meets the specific requirements of various industries. For buyers and manufacturers alike, familiarity with certifications such as ISO standards, CE markings, and industry-specific validations can provide a competitive edge in a growing market, projected to reach significant value by 2030.

The global optical coating equipment market is experiencing robust growth, fueled by advances in technology and increased demand in sectors like automotive and electronics. This upward trend underscores the importance of adhering to standards, as it directly correlates with market acceptance and performance reliability. As the industry progresses, staying updated on the latest certification requirements and industry trends will be essential for businesses looking to innovate and expand their reach in the optical coating landscape.

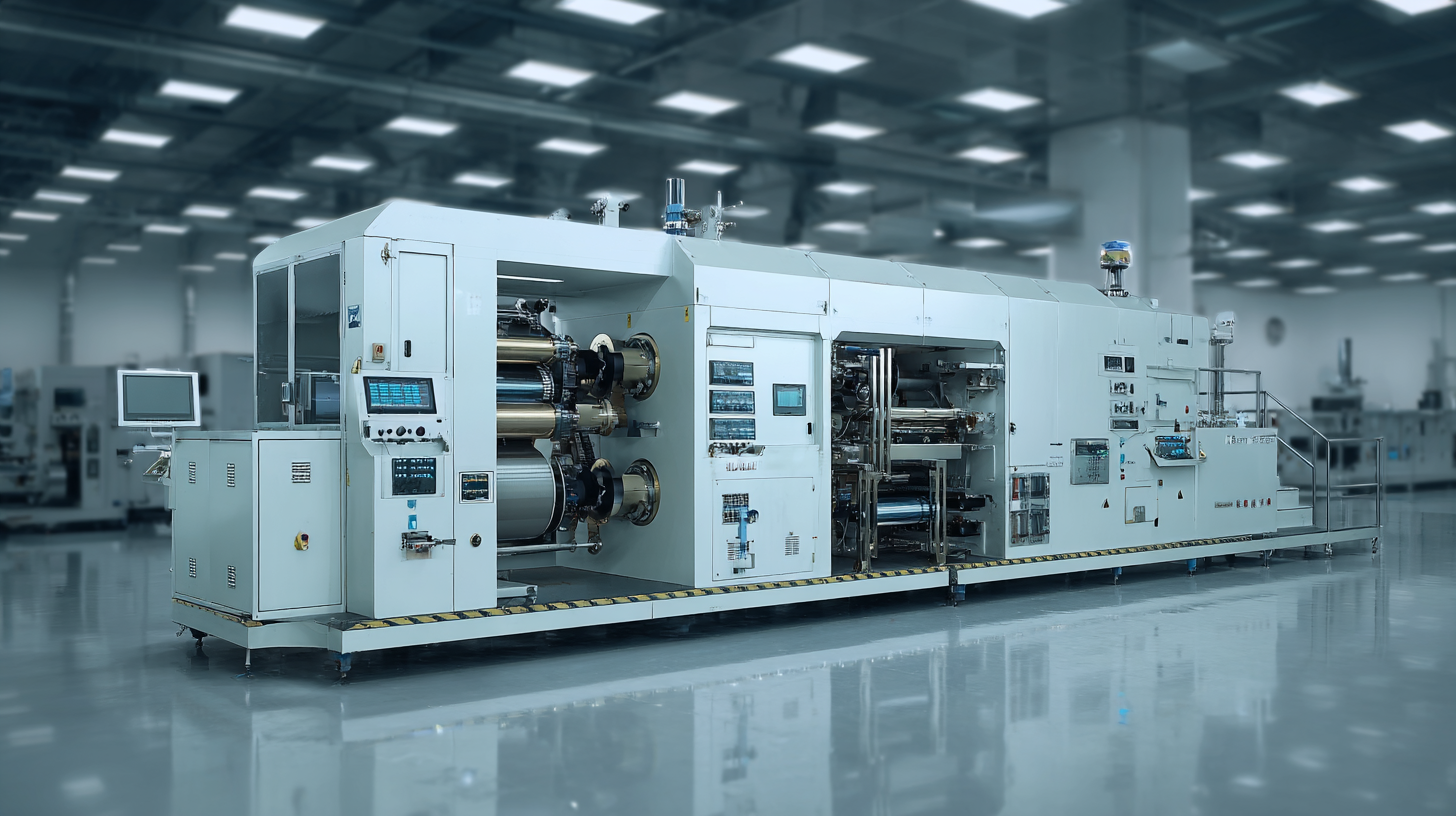

In recent years, the optical film coating equipment sector has witnessed remarkable growth driven by technological advancements and increasing demand across various industries. The proliferation of electronic devices with enhanced screen technologies, such as smartphones, tablets, and televisions, has necessitated high-quality optical films that improve visual performance. This trend has spurred investments in cutting-edge coating machines, allowing manufacturers to produce films with enhanced durability and superior optical clarity.

Another significant growth driver in this sector is the rising emphasis on energy efficiency and sustainability. As industries become more environmentally conscious, the demand for optical films that contribute to energy savings and reduce carbon footprints is rapidly increasing. Manufacturers are focusing on developing machines that not only produce high-performance films but also utilize eco-friendly materials and processes. This shift not only aligns with global sustainability goals but also opens new avenues for innovative product offerings and enhanced market competitiveness in the optical film coating landscape.

Navigating the complexities of import-export certifications can be daunting for manufacturers of optical film coating machines. However, adhering to quality standards and compliance is crucial for ensuring the safety and efficacy of coating processes. Certified machines not only enhance production efficiency but also mitigate risks associated with non-compliance. The quality of optical films largely depends on the machines used in their production, making it essential for manufacturers to invest in equipment that meets international standards.

Compliance with regulations such as ISO 9001 ensures that the coating processes are consistent and reliable. This certification involves a comprehensive assessment of quality management systems, emphasizing continuous improvement and customer satisfaction. Moreover, safety standards, such as OSHA regulations, protect workers operating these machines, highlighting the importance of both product quality and workforce safety. By prioritizing these standards, manufacturers can build trust with their clients and ensure their products meet the stringent demands of the optical industry.

China has emerged as a powerhouse in the production of optical film coating machines, significantly impacting the global market. According to a recent report by Technavio, the global optical films market is expected to grow by over $7 billion between 2021 and 2025, with China leading the charge due to its advanced manufacturing capabilities and innovative technologies. Companies like Bole Technology and Jufeng Optoelectronics are at the forefront, developing machines that offer superior performance and energy efficiency, catering to the increasing demand for high-quality optical films used in displays and other applications.

The innovation in optical film solutions is further supported by China's robust investment in research and development. The Ministry of Industry and Information Technology (MIIT) reported that investment in optoelectronic technology has surged by 15% annually, fueling advancements in production processes and machine capabilities. As top manufacturers continuously strive for improved efficiency and output quality, the availability of advanced optical film coating machines is set to enhance the performance of displays, smartphones, and various electronic devices, solidifying China's position as a leader in the optical film industry.

| Parameter | Description | Value |

|---|---|---|

| Machine Type | Optical Film Coating Machine | - |

| Certification Standards | ISO 9001, CE | - |

| Production Capacity | Monthly Output | 100 units |

| Average Lead Time | Time from order to delivery | 4-6 weeks |

| Key Features | Automation, High Precision | - |

| Export Markets | Regions served | Asia, Europe, North America |