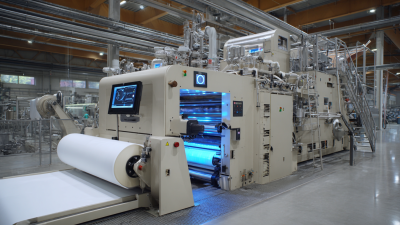

In today's fast-paced manufacturing landscape, optimizing production processes is crucial for maintaining competitive advantage. One of the most transformative technologies in coating applications is the Slot Die Coating Machine, which enhances precision and efficiency in various industries, including electronics, photovoltaics, and flexible packaging. According to a recent market analysis by Smithers Pira, the demand for advanced coating technologies is projected to grow by over 8% annually, driven by the need for high-quality coatings that minimize waste and reduce costs. Slot die coating, in particular, offers unique benefits such as uniform coating thickness, reduced material consumption, and improved scalability, making it an ideal choice for manufacturers aiming for operational excellence. As we explore effective strategies to optimize the use of Slot Die Coating Machines, we will uncover key practices and insights that can elevate production standards and foster innovation in coating applications.

Slot die coating technology has made significant strides in various industries, especially in the production of advanced materials such as vinyl-PDMS composite membranes and perovskite solar cells. Recent studies have demonstrated the effectiveness of slot die coating for achieving high-performance coatings with precise control over thickness and uniformity. For instance, the use of slot die coating in the fabrication of vinyl-PDMS composite membranes has shown potential for applications in alcohol perm-selective pervaporation, highlighting the technique's versatility in producing functional films.

Moreover, developments in perovskite solar cells have further showcased the advantages of slot die coating. Research led by the University of Electronic Science and Technology of China achieved an impressive 20.3% efficiency in mini inverted perovskite solar modules through this method. This scalable approach not only enhances manufacturing efficiency but also facilitates the usage of novel additives that improve the overall performance and stability of solar cells. As companies aim to meet the growing energy demands with sustainable solutions, slot die coating continues to be a cornerstone technology delivering high-quality films for a range of applications.

| Application | Material Used | Coating Thickness (µm) | Production Speed (m/min) | Advantages |

|---|---|---|---|---|

| Flexible Electronics | Conductive Polymer | 1-5 | 50 | High precision and uniformity |

| Solar Cells | Silicon-based Material | 5-15 | 30 | Improved energy efficiency |

| Medical Devices | Biocompatible Coatings | 2-10 | 25 | Enhanced safety and performance |

| Automotive Parts | Corrosion-resistant Coatings | 10-20 | 20 | Durability and longer lifespan |

| Electronics | Insulative Coatings | 0.5-2 | 40 | Reduced electrical interference |

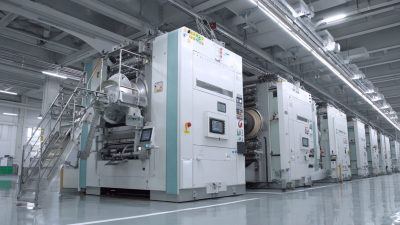

Slot die coating machines are becoming increasingly vital in enhancing production efficiency across various advanced manufacturing sectors, particularly in the production of lithium-ion batteries and perovskite solar cells. These machines offer significant advantages, including impeccable uniformity and minimal waste during the coating process. By using slot die technology, manufacturers can achieve accurate control over film thickness, leading to improved product quality and performance.

**Tip 1:** When implementing slot die coating into your production line, ensure precise alignment and maintenance of the equipment. Regular calibration can mitigate thickness variability, which is crucial for achieving optimal results in high-efficiency products like perovskite solar cells.

The scalability of slot die coating technology is also a major benefit. As the demand for renewable energy solutions and advanced battery technologies continues to grow, manufacturers can leverage slot die machines to produce larger areas of coated materials efficiently. This scalability not only cuts down production time but also allows for significant cost savings in the long run.

**Tip 2:** Invest in staff training and skill development focused on the operation and troubleshooting of slot die coating machines. A well-trained team can maximize machine performance and adapt quickly to any challenges that arise during production, ensuring continuity and efficiency in manufacturing processes.

The evolution of coating technologies has sparked a compelling debate between slot die coating and traditional methods. Recent studies indicate that slot die coating can significantly enhance the uniformity of thin films, crucial for applications in perovskite photovoltaics. A comprehensive review highlighted that slot die coating not only minimizes waste but also allows for a continuous production process, which traditional methods often fail to achieve. This shift towards slot die technology is backed by its ability to facilitate large-area coating with precise thickness control, contributing to higher power conversion efficiencies (PCE) in solar cells.

Moreover, cost analysis reveals that even though the initial setup for slot die coating might be higher, the long-term benefits, including reduced material waste and lower operational costs, render it more economical. For instance, recent findings suggest that perovskite-organic tandem solar cells manufactured with slot die techniques can achieve up to a 20% reduction in production costs when compared to conventional spin-coating methods. By leveraging the advantages of this cutting-edge technology, manufacturers can optimize their operations and contribute to a more sustainable and efficient future in solar energy production.

Slot die coating machines have become essential in optimizing production processes across various industries, particularly in the manufacturing of thin films and coatings. According to a recent report by Smithers Pira, the global market for slot die coating technology is projected to reach $1.2 billion by 2025, representing a significant growth spurred by efficiency gains and cost-effectiveness. Industries utilizing this technology report reductions in material waste by up to 30%, thus translating to considerable cost savings over time.

In terms of production rates, slot die coating can offer a throughput that exceeds traditional coating methods. For example, a study published in the Journal of Coatings Technology and Research highlights that slot die coating can achieve application speeds of up to 100 meters per minute, depending on the substrate and coating material. This high-speed capability not only accelerates production cycles but also enhances the uniformity and quality of coatings applied, resulting in products that meet stringent industry standards. By integrating slot die coating machines into their production lines, manufacturers are poised to achieve a competitive edge in both efficiency and cost reduction.

As the demand for precision and efficiency in manufacturing processes continues to grow, slot die coating technology is poised for significant advancements. The future of this technology lies in its ability to streamline operations while consistently delivering high-quality coatings. Innovations such as automated real-time monitoring systems and the integration of AI for process optimization are expected to enhance efficiency and reduce waste. These trends not only promise to improve production outputs but also offer substantial cost savings for manufacturers.

Tip: To stay ahead in the evolving market, consider investing in training your team on the latest slot die coating techniques and technologies. Knowledgeable staff can better implement new systems, ensuring a smoother transition and optimizing production.

Additionally, as sustainability becomes a critical concern, the market potential for eco-friendly coating solutions is expanding. Manufacturers that adopt solvent-free and water-based formulas will not only meet regulatory standards but also attract environmentally conscious clients. This trend opens new avenues for growth and positions companies at the forefront of sustainable manufacturing practices.

Tip: Regularly assess your current coating processes and materials. Adopting sustainable practices now can lead to long-term benefits and align your business with future market demands.