In today's competitive manufacturing landscape, the quest for precision and efficiency drives companies to adopt advanced technologies that enhance production processes. One such innovation that has gained significant traction is the Slot Die Coating Machine. This specialized equipment offers distinct advantages in coating applications, making it an invaluable asset for various industries, including electronics, automotive, and packaging. By ensuring consistent and uniform application of coatings, a Slot Die Coating Machine can significantly improve product quality while reducing waste and production costs.

As businesses strive to optimize their operations, the choice of coating technology is paramount. The Slot Die Coating Machine stands out for its ability to deliver precise and controlled coating thickness, which is essential for products requiring high-quality surfaces and performance. Furthermore, the scalability and adaptability of this machine make it suitable for both small batch productions and larger-scale operations, providing manufacturers with the flexibility needed to meet diverse market demands. In this article, we will explore the benefits and features of the Slot Die Coating Machine, highlighting why it has become a preferred choice for manufacturers looking to elevate their production capabilities.

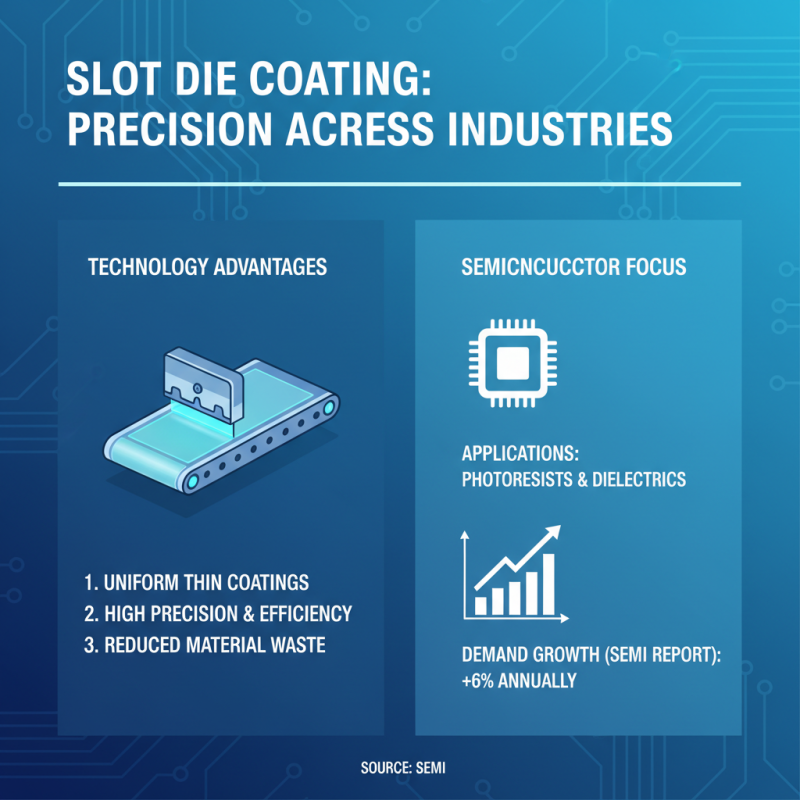

Slot die coating technology has become a pivotal method in various industries, particularly for applications requiring uniform film thickness. This technology employs a precision slot die, which allows for the consistent application of coatings across various substrates, ensuring minimal waste and high efficiency. Reports indicate that the global slot die coating market is projected to grow at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, driven by advancements in manufacturing processes and the increasing demand for high-quality coated products.

One of the key advantages of slot die coating is its ability to handle a wide range of viscosities, accommodating everything from low-viscosity inks to high-viscosity adhesives. This flexibility is crucial for industries such as electronics, where precise layering of materials is essential for the performance of components like displays and batteries. A study published by the Coating & Drying Technology journal highlights that the uniformity of layers applied via slot die methods can improve the performance and lifespan of finished products by as much as 20%, reinforcing the importance of this technology in achieving optimal results.

Moreover, the environmental impact of manufacturing processes is increasingly scrutinized, leading to a shift towards more sustainable practices. Slot die coating minimizes material waste and energy consumption compared to traditional coating methods, such as spray coating, which can lead to significant overspray and resource inefficiency. According to a report by Market Research Future, industries adopting slot die technology can reduce material waste by up to 30%, aligning with the growing trend towards eco-friendly production methods and better resource management.

Slot die coating machines have emerged as a preferred choice in various production settings due to their numerous advantages. One of the primary benefits of using slot die coating technology is the ability to achieve uniform coating thickness. This precision is crucial in industries where consistency impacts the quality and performance of the final product. By providing an even application of materials, manufacturers can reduce waste and enhance the efficiency of their processes.

Moreover, slot die coating machines boast impressive speed and scalability, making them ideal for high-volume production. These machines can handle a diverse range of materials, including polymers, adhesives, and paints, streamlining the manufacturing process. Their versatility about substrate compatibility allows for increased productivity without compromising quality, which is essential for meeting the demands of today’s fast-paced markets.

Tips for optimizing your slot die coating process include regularly maintaining the equipment to avoid downtime and conducting thorough tests on initial runs to ensure quality standards are met. Additionally, consider experimenting with different slot die configurations to find the perfect fit for your specific materials and application needs, as this can significantly enhance coating performance and efficiency.

Slot die coating technology is rapidly gaining traction across various industries due to its precision and efficiency in applying thin and uniform coatings. In the semiconductor industry, for instance, the slot die coating process is used to deposit photoresists and dielectric materials with exceptional accuracy. According to a report by the Semiconductor Equipment and Materials International (SEMI), the demand for advanced coating technologies in semiconductor manufacturing is projected to grow by 6% annually, highlighting the critical role that slot die machines will play in meeting this need.

In the renewable energy sector, slot die coating is essential for manufacturing photovoltaic cells. A study from the National Renewable Energy Laboratory (NREL) indicates that the use of slot die technology can enhance the efficiency of solar panels by ensuring better uniformity of conductive materials. This precision helps to maximize the power conversion efficiency, with recent advancements suggesting potential increases of up to 2% in efficiency rates when compared to traditional coating techniques. Additionally, the flexibility of slot die machines allows for processing a variety of substrates, making them ideal for the diverse material requirements in renewable energy applications.

Furthermore, in the pharmaceutical sector, the application of slot die coating has proven invaluable for drug delivery systems. A report from the International Journal of Pharmaceutics highlights how slot die technology facilitates the precise coating of drug particles, which can lead to improved bioavailability and targeted delivery. As companies strive for greater efficiency and effectiveness in their production processes, the trend towards slot die coating is becoming increasingly prominent, signaling a transformative shift in how products across multiple industries are manufactured.

When considering a slot die coating machine for your production line, several factors come into play to ensure you make the right choice. First and foremost, assess the type of materials you will be working with. Different coatings require specific viscosities, and selecting a machine that accommodates your material requirements is crucial for achieving optimal results. Additionally, consider the machine's compatibility with various substrates, as this will affect the versatility of your production capabilities.

Another important aspect is the machine's ease of use and maintenance. Opt for a slot die coating machine that offers user-friendly controls and is easy to clean. This not only enhances productivity but also reduces downtime, which is vital for meeting production deadlines. Pay attention to the machinery's design; a well-engineered system can simplify adjustments and lead to better coating uniformity.

**Tip:** Always inquire about the availability of technical support and training resources, as they play a critical role in maximizing the efficiency of your investment. Furthermore, evaluate the machine's scalability to ensure it can adapt to your future production needs without requiring a complete overhaul. By carefully weighing these factors, you can select the most suitable slot die coating machine for your operations.

This chart illustrates the important factors to consider when selecting a slot die coating machine based on their perceived impact on production efficiency and quality.

Slot die coating machines have become an integral part of many manufacturing processes, thanks to their ability to deliver cost efficiency and enhanced production quality. According to a recent report by the Coating Industry Association, manufacturers that employ slot die technology can reduce coating material waste by as much as 30%. This efficiency stems from the precise control of the coating thickness and distribution, allowing businesses to optimize resource usage while minimizing excess material costs.

Moreover, the consistency in coating quality that slot die machines provide is crucial for industries requiring high-performance applications, such as electronics and automotive manufacturing. A study published in the Journal of Coatings Technology highlighted that the uniformity of coatings applied through slot die methods often exceeds that of traditional coating techniques by nearly 50%. This translation into better adhesion, improved surface properties, and enhanced durability can significantly lower the reject rates in production lines, ultimately driving overall profitability. By investing in slot die coating machines, companies can achieve a higher yield of quality products, reinforcing their competitive edge in the market.

| Feature | Description | Benefits | Cost Impact ($) |

|---|---|---|---|

| Precision Coating | Uniform thickness of coating | Increased product quality | Reduces material wastage by 15% |

| Versatile Applications | Can coat various materials | Adaptability for different products | Maximizes production flexibility |

| Automated Processes | Reduced manual intervention | Consistent quality and output | Lowers labor costs by 10% |

| Reduced Setup Time | Quick changeover between runs | Increased operational efficiency | Decreases downtime costs by 20% |

| Environmentally Friendly | Lower solvent usage | Minimizes environmental impact | Potential savings on waste disposal |