Key FeaturesSmall Lab Coating Machine: Multifunctional Heated Blade Coater

Reduced Labor Costs: Cut down on labor expenses by automating the coating process, freeing up your workforce for other critical tasks.

Material Savings: Optimize material usage with precise application, reducing waste and lowering overall production costs.

Multi-Substrate Compatibility: Whether you’re working with metal, plastic, wood, or glass, our machine adapts seamlessly to various substrates, providing a flawless finish every time.

Customizable Settings: Tailor the coating parameters to suit different projects, ensuring optimal results for a wide range of applications.

Material Savings: Optimize material usage with precise application, reducing waste and lowering overall production costs.

Multi-Substrate Compatibility: Whether you’re working with metal, plastic, wood, or glass, our machine adapts seamlessly to various substrates, providing a flawless finish every time.

Customizable Settings: Tailor the coating parameters to suit different projects, ensuring optimal results for a wide range of applications.

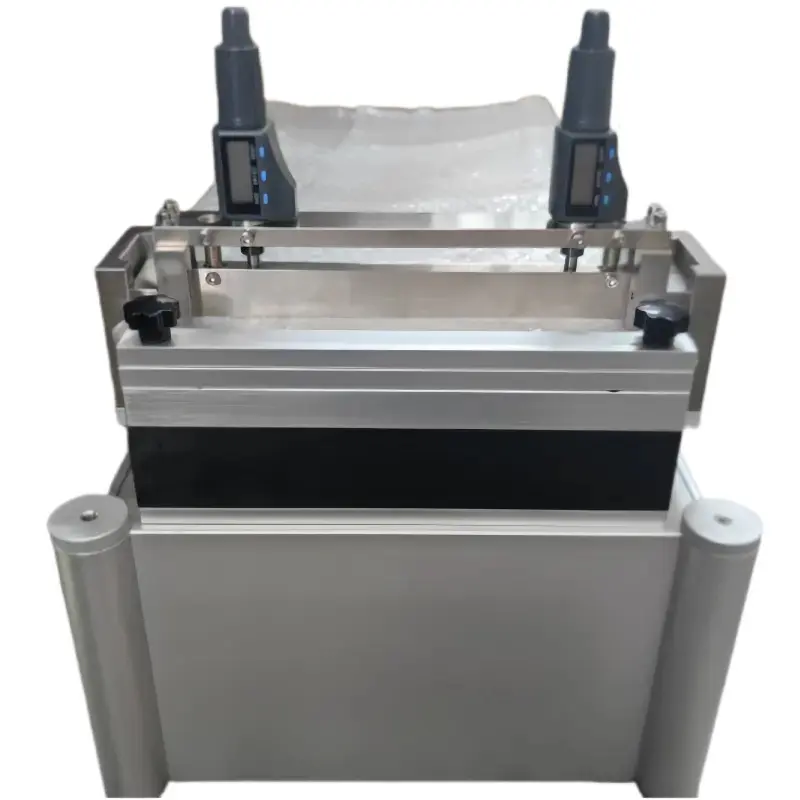

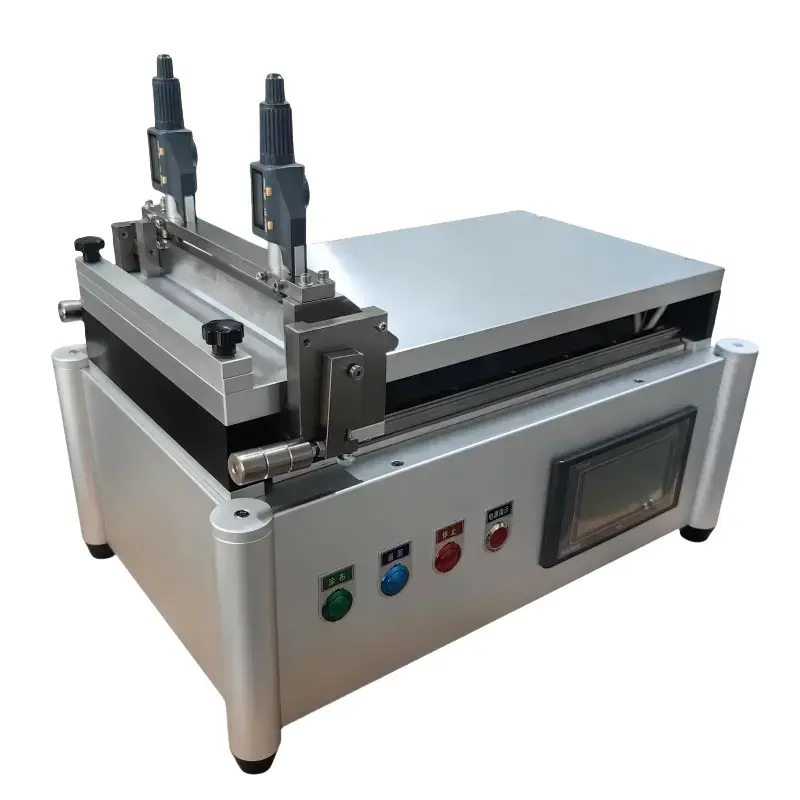

Product Detail

The laboratory coating machine is a crucial instrument for researchers looking to apply consistent coatings on various substrates. It excels in handling different materials, including high-viscosity solutions, such as polymers and adhesives. This machine is designed for precision, ensuring uniform layer thickness, which is essential for experiments requiring exacting standards.

description2

Product parameters

| Model | MS-SY300 |

| Control System | Self-developed by Maosen / PLC with touchscreen |

| Coating Method | Doctor blade / rod coating integrated (separately for each coating) |

| Doctor Blade Adjustment | Pull-up style (doctor blade is removable for easy cleaning) |

| Coating Speed | Digital setting 1-5 meters per minute |

| Length Setting | Digital setting 10-300 mm |

| Temperature Control | Room temperature to 160°C (constant temperature) |

| Leveling Device | Equipped with a leveling bar to flatten the material before coating |

| Table Surface Material | Aluminum alloy + glass (removable) |

| Coating Uniformity | ±4% (depending on material flatness) |

| Working Area | 200*300 mm |

| Coating Thickness | 0.005-5 mm (wet film) |

| Machine Dimensions | Length 550 mm * Width 350 mm * Height 350 mm (approx.) |

| Machine Weight | Net weight 28 kg (approx.) |

| Rod Device | Comes with a rod holder (rod needs to be purchased separately, one rod per thickness) |

| Rod Weights | Includes two adjustable weights |

| Rod Size | Diameter 10 mm * Length 300 mm (standard) |

| Doctor Blade Material | Alloy stainless steel |

| Power Supply | Voltage 110-220V 50Hz |

| Power Consumption | 48W (standby) 2000W (heating) |

| Notes | For low viscosity and high precision, the rod coating machine is more effective. For high viscosity, the doctor blade coating is better! |

0102